Page 83 - Renewable Energy Devices and System with Simulations in MATLAB and ANSYS

P. 83

70 Renewable Energy Devices and Systems with Simulations in MATLAB and ANSYS ®

®

PV array

PV strings

PV modules

Multistring Module-integrated

Central inverter converter

inverter

AC bus

AC bus AC bus

(a) (b) (c)

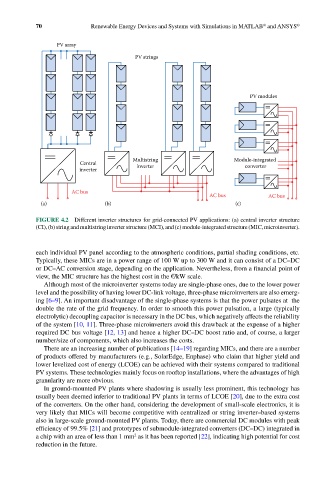

FIGURE 4.2 Different inverter structures for grid-connected PV applications: (a) central inverter structure

(CI), (b) string and multistring inverter structure (MCI), and (c) module-integrated structure (MIC, microinverter).

each individual PV panel according to the atmospheric conditions, partial shading conditions, etc.

Typically, these MICs are in a power range of 100 W up to 300 W and it can consist of a DC–DC

or DC–AC conversion stage, depending on the application. Nevertheless, from a financial point of

view, the MIC structure has the highest cost in the €/kW scale.

Although most of the microinverter systems today are single-phase ones, due to the lower power

level and the possibility of having lower DC-link voltage, three-phase microinverters are also emerg-

ing [6–9]. An important disadvantage of the single-phase systems is that the power pulsates at the

double the rate of the grid frequency. In order to smooth this power pulsation, a large (typically

electrolytic) decoupling capacitor is necessary in the DC bus, which negatively affects the reliability

of the system [10, 11]. Three-phase microinverters avoid this drawback at the expense of a higher

required DC bus voltage [12, 13] and hence a higher DC–DC boost ratio and, of course, a larger

number/size of components, which also increases the costs.

There are an increasing number of publications [14–19] regarding MICs, and there are a number

of products offered by manufacturers (e.g., SolarEdge, Enphase) who claim that higher yield and

lower levelized cost of energy (LCOE) can be achieved with their systems compared to traditional

PV systems. These technologies mainly focus on rooftop installations, where the advantages of high

granularity are more obvious.

In ground-mounted PV plants where shadowing is usually less prominent, this technology has

usually been deemed inferior to traditional PV plants in terms of LCOE [20], due to the extra cost

of the converters. On the other hand, considering the development of small-scale electronics, it is

very likely that MICs will become competitive with centralized or string inverter–based systems

also in large-scale ground-mounted PV plants. Today, there are commercial DC modules with peak

efficiency of 99.5% [21] and prototypes of submodule-integrated converters (DC–DC) integrated in

a chip with an area of less than 1 mm as it has been reported [22], indicating high potential for cost

2

reduction in the future.