Page 252 - Robot Builders Source Book - Gordon McComb

P. 252

240 Feeding and Orientation Devices

shut-off mechanism 2 pushes the blanks sideways, bringing them from the bottom of

the box to channel 5.

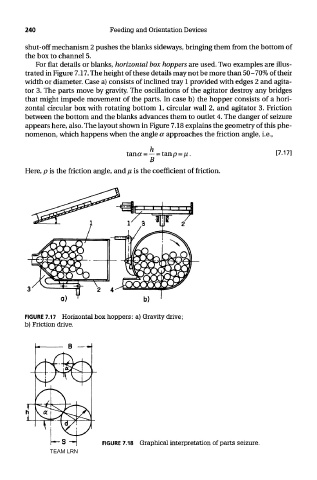

For flat details or blanks, horizontal box hoppers are used. Two examples are illus-

trated in Figure 7.17. The height of these details may not be more than 50-70% of their

width or diameter. Case a) consists of inclined tray 1 provided with edges 2 and agita-

tor 3. The parts move by gravity. The oscillations of the agitator destroy any bridges

that might impede movement of the parts. In case b) the hopper consists of a hori-

zontal circular box with rotating bottom 1, circular wall 2, and agitator 3. Friction

between the bottom and the blanks advances them to outlet 4. The danger of seizure

appears here, also. The layout shown in Figure 7.18 explains the geometry of this phe-

nomenon, which happens when the angle a approaches the friction angle, i.e.,

Here, p is the friction angle, and n is the coefficient of friction.

FIGURE 7.17 Horizontal box hoppers: a) Gravity drive;

b) Friction drive.

FIGURE 7.18 Graphical interpretation of parts seizure.

TEAM LRN