Page 254 - Robot Builders Source Book - Gordon McComb

P. 254

242 Feeding and Orientation Devices

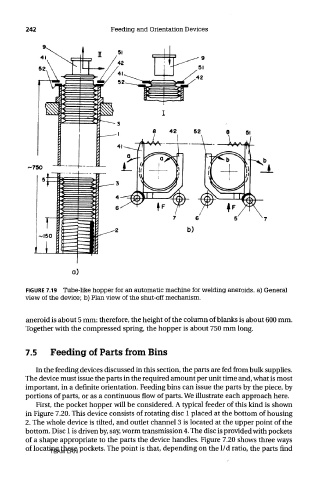

FIGURE 7.19 Tube-like hopper for an automatic machine for welding aneroids, a) General

view of the device; b) Plan view of the shut-off mechanism.

aneroid is about 5 mm: therefore, the height of the column of blanks is about 600 mm.

Together with the compressed spring, the hopper is about 750 mm long.

7.5 Feeding of Parts from Bins

In the feeding devices discussed in this section, the parts are fed from bulk supplies.

The device must issue the parts in the required amount per unit time and, what is most

important, in a definite orientation. Feeding bins can issue the parts by the piece, by

portions of parts, or as a continuous flow of parts. We illustrate each approach here.

First, the pocket hopper will be considered. A typical feeder of this kind is shown

in Figure 7.20. This device consists of rotating disc 1 placed at the bottom of housing

2. The whole device is tilted, and outlet channel 3 is located at the upper point of the

bottom. Disc 1 is driven by, say, worm transmission 4. The disc is provided with pockets

of a shape appropriate to the parts the device handles. Figure 7.20 shows three ways

of locating these pockets. The point is that, depending on the 1/d ratio, the parts find

TEAM LRN