Page 69 - Robot Builders Source Book - Gordon McComb

P. 69

58 Concepts and Layouts

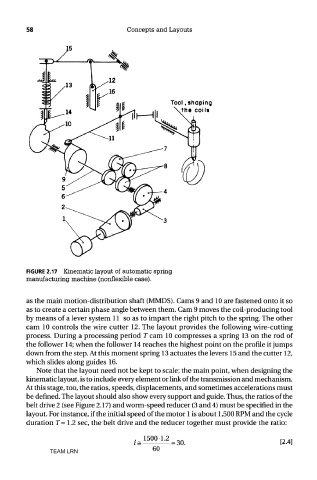

FIGURE 2.17 Kinematic layout of automatic spring

manufacturing machine (nonflexible case).

as the main motion-distribution shaft (MMDS). Cams 9 and 10 are fastened onto it so

as to create a certain phase angle between them. Cam 9 moves the coil-producing tool

by means of a lever system 11 so as to impart the right pitch to the spring. The other

cam 10 controls the wire cutter 12. The layout provides the following wire-cutting

process. During a processing period T cam 10 compresses a spring 13 on the rod of

the follower 14; when the follower 14 reaches the highest point on the profile it jumps

down from the step. At this moment spring 13 actuates the levers 15 and the cutter 12,

which slides along guides 16.

Note that the layout need not be kept to scale; the main point, when designing the

kinematic layout, is to include every element or link of the transmission and mechanism.

At this stage, too, the ratios, speeds, displacements, and sometimes accelerations must

be defined. The layout should also show every support and guide. Thus, the ratios of the

belt drive 2 (see Figure 2.17) and worm-speed reducer (3 and 4) must be specified in the

layout. For instance, if the initial speed of the motor 1 is about 1,500 RPM and the cycle

duration T=\2 sec, the belt drive and the reducer together must provide the ratio:

TEAM LRN