Page 86 - Rotating Machinery Pratical Solutions to Unbalance and Misalignment

P. 86

Rotating Machinery: Practical Solutions

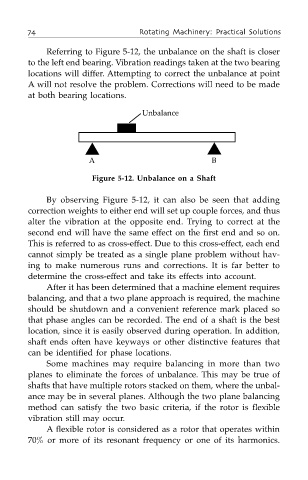

Referring to Figure 5-12, the unbalance on the shaft is closer

to the left end bearing. Vibration readings taken at the two bearing

locations will differ. Attempting to correct the unbalance at point

A will not resolve the problem. Corrections will need to be made

at both bearing locations.

Unbalance

▲ ▲

A B

Figure 5-12. Unbalance on a Shaft

By observing Figure 5-12, it can also be seen that adding

correction weights to either end will set up couple forces, and thus

alter the vibration at the opposite end. Trying to correct at the

second end will have the same effect on the first end and so on.

This is referred to as cross-effect. Due to this cross-effect, each end

cannot simply be treated as a single plane problem without hav-

ing to make numerous runs and corrections. It is far better to

determine the cross-effect and take its effects into account.

After it has been determined that a machine element requires

balancing, and that a two plane approach is required, the machine

should be shutdown and a convenient reference mark placed so

that phase angles can be recorded. The end of a shaft is the best

location, since it is easily observed during operation. In addition,

shaft ends often have keyways or other distinctive features that

can be identified for phase locations.

Some machines may require balancing in more than two

planes to eliminate the forces of unbalance. This may be true of

shafts that have multiple rotors stacked on them, where the unbal-

ance may be in several planes. Although the two plane balancing

method can satisfy the two basic criteria, if the rotor is flexible

vibration still may occur.

A flexible rotor is considered as a rotor that operates within

70% or more of its resonant frequency or one of its harmonics.