Page 247 - Semiconductor Manufacturing Handbook

P. 247

Geng(SMH)_CH17.qxd 04/04/2005 19:57 Page 17.2

CHEMICAL MECHANICAL POLISHING

17.2 WAFER PROCESSING

Slurry supply

Carrier pad

Chuck Slurry Polishing pad

Wafer

Carrier Polishing table

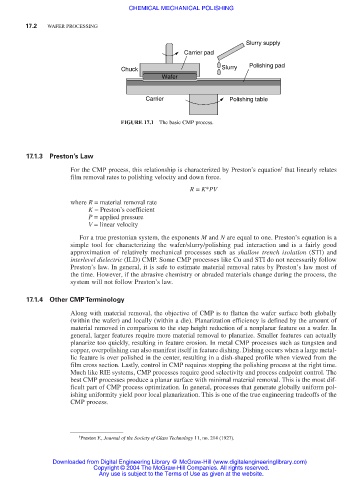

FIGURE 17.1 The basic CMP process.

17.1.3 Preston’s Law

†

For the CMP process, this relationship is characterized by Preston’s equation that linearly relates

film removal rates to polishing velocity and down force.

R = K*PV

where R = material removal rate

K = Preston’s coefficient

P = applied pressure

V = linear velocity

For a true prestonian system, the exponents M and N are equal to one. Preston’s equation is a

simple tool for characterizing the wafer/slurry/polishing pad interaction and is a fairly good

approximation of relatively mechanical processes such as shallow trench isolation (STI) and

interlevel dielectric (ILD) CMP. Some CMP processes like Cu and STI do not necessarily follow

Preston’s law. In general, it is safe to estimate material removal rates by Preston’s law most of

the time. However, if the abrasive chemistry or abraded materials change during the process, the

system will not follow Preston’s law.

17.1.4 Other CMP Terminology

Along with material removal, the objective of CMP is to flatten the wafer surface both globally

(within the wafer) and locally (within a die). Planarization efficiency is defined by the amount of

material removed in comparison to the step height reduction of a nonplanar feature on a wafer. In

general, larger features require more material removal to planarize. Smaller features can actually

planarize too quickly, resulting in feature erosion. In metal CMP processes such as tungsten and

copper, overpolishing can also manifest itself in feature dishing. Dishing occurs when a large metal-

lic feature is over polished in the center, resulting in a dish-shaped profile when viewed from the

film cross section. Lastly, control in CMP requires stopping the polishing process at the right time.

Much like RIE systems, CMP processes require good selectivity and process endpoint control. The

best CMP processes produce a planar surface with minimal material removal. This is the most dif-

ficult part of CMP process optimization. In general, processes that generate globally uniform pol-

ishing uniformity yield poor local planarization. This is one of the true engineering tradeoffs of the

CMP process.

† Preston F., Journal of the Society of Glass Technology 11, no. 214 (1927).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.