Page 196 - Sensors and Control Systems in Manufacturing

P. 196

Electrical Fiber Optics in Sensors and Contr ol Systems 157

Light Pulse

Light Pulse

Electrical

Pulse Pulse

In Out

Electrical Light

To To

Light Electrical

Conversion Conversion

LED Photo

Light Source Detector

Electrical Pulse Out

Equals Electrical Pulse In

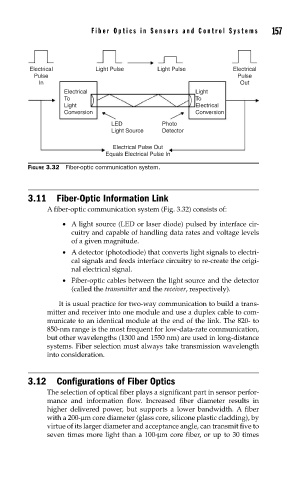

FIGURE 3.32 Fiber-optic communication system.

3.11 Fiber-Optic Information Link

A fiber-optic communication system (Fig. 3.32) consists of:

• A light source (LED or laser diode) pulsed by interface cir-

cuitry and capable of handling data rates and voltage levels

of a given magnitude.

• A detector (photodiode) that converts light signals to electri-

cal signals and feeds interface circuitry to re-create the origi-

nal electrical signal.

• Fiber-optic cables between the light source and the detector

(called the transmitter and the receiver, respectively).

It is usual practice for two-way communication to build a trans-

mitter and receiver into one module and use a duplex cable to com-

municate to an identical module at the end of the link. The 820- to

850-nm range is the most frequent for low-data-rate communication,

but other wavelengths (1300 and 1550 nm) are used in long-distance

systems. Fiber selection must always take transmission wavelength

into consideration.

3.12 Configurations of Fiber Optics

The selection of optical fiber plays a significant part in sensor perfor-

mance and information flow. Increased fiber diameter results in

higher delivered power, but supports a lower bandwidth. A fiber

with a 200-μm core diameter (glass core, silicone plastic cladding), by

virtue of its larger diameter and acceptance angle, can transmit five to

seven times more light than a 100-μm core fiber, or up to 30 times