Page 200 - Sensors and Control Systems in Manufacturing

P. 200

Fiber Optics in Sensors and Contr ol Systems

Active Handshake 161

Carrier

Fiber Optic Fiber Optic

Processor Terminal

Line Driver Line Driver

Fiber Optic Cable

Fiber Optic Terminal

Line Driver

Fiber Optic Terminal

Line Driver

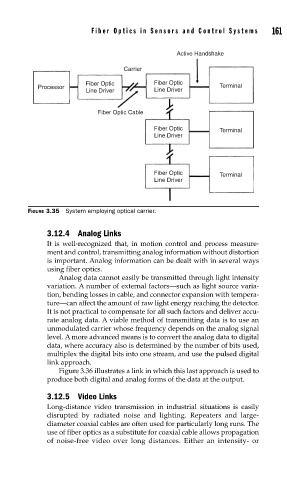

FIGURE 3.35 System employing optical carrier.

3.12.4 Analog Links

It is well-recognized that, in motion control and process measure-

ment and control, transmitting analog information without distortion

is important. Analog information can be dealt with in several ways

using fiber optics.

Analog data cannot easily be transmitted through light intensity

variation. A number of external factors—such as light source varia-

tion, bending losses in cable, and connector expansion with tempera-

ture—can affect the amount of raw light energy reaching the detector.

It is not practical to compensate for all such factors and deliver accu-

rate analog data. A viable method of transmitting data is to use an

unmodulated carrier whose frequency depends on the analog signal

level. A more advanced means is to convert the analog data to digital

data, where accuracy also is determined by the number of bits used,

multiplex the digital bits into one stream, and use the pulsed digital

link approach.

Figure 3.36 illustrates a link in which this last approach is used to

produce both digital and analog forms of the data at the output.

3.12.5 Video Links

Long-distance video transmission in industrial situations is easily

disrupted by radiated noise and lighting. Repeaters and large-

diameter coaxial cables are often used for particularly long runs. The

use of fiber optics as a substitute for coaxial cable allows propagation

of noise-free video over long distances. Either an intensity- or