Page 390 - Sensors and Control Systems in Manufacturing

P. 390

344

Cha p te r

Se v e n

ter

a

i

a

Material B

M

l B

Material B d 0 + δd 0

Material A d 0

Material A

Material A

Material A

Material B

Material B

> α , δd < 0

Temperature coefficient α A B 0

(a) (b)

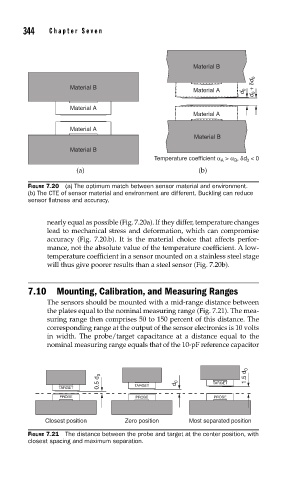

FIGURE 7.20 (a) The optimum match between sensor material and environment.

(b) The CTE of sensor material and environment are different. Buckling can reduce

sensor fl atness and accuracy.

nearly equal as possible (Fig. 7.20a). If they differ, temperature changes

lead to mechanical stress and deformation, which can compromise

accuracy (Fig. 7.20.b). It is the material choice that affects perfor-

mance, not the absolute value of the temperature coefficient. A low-

temperature coefficient in a sensor mounted on a stainless steel stage

will thus give poorer results than a steel sensor (Fig. 7.20b).

7.10 Mounting, Calibration, and Measuring Ranges

The sensors should be mounted with a mid-range distance between

the plates equal to the nominal measuring range (Fig. 7.21). The mea-

suring range then comprises 50 to 150 percent of this distance. The

corresponding range at the output of the sensor electronics is 10 volts

in width. The probe/target capacitance at a distance equal to the

nominal measuring range equals that of the 10-pF reference capacitor

0.5 d 0 d 0 TARGET 1.5 d 0

TARGET TARGET

PROBE PROBE PROBE

Closest position Zero position Most separated position

FIGURE 7.21 The distance between the probe and target at the center position, with

closest spacing and maximum separation.