Page 395 - Sensors and Control Systems in Manufacturing

P. 395

Industrial Sensors and Contr ol

Transmitting fibers 349

Input light

Object

Output light

Receiving fibers Distance d

FIGURE 7.28 The principle of operation of a fi ber-optic mechanical sensor

using a Y-guide probe.

a bifurcated fiber bundle. The light emitted from one bundle is back-

reflected by the object to be measured and collected by another bun-

dle (receiving fibers). As a result, the returned light at the detector is

intensity-modulated to a degree dependent on the distance between

the end of the fiber bundle and the object. The sensitivity and the

dynamic range are determined by the geometrical arrangement of the

array of fiber bundles and by both the number and type of the fibers.

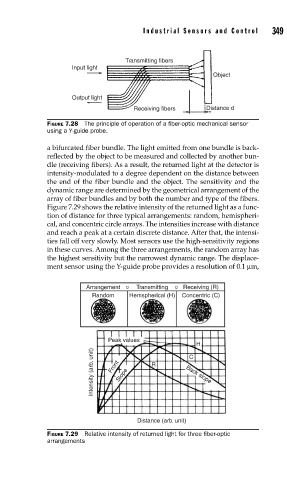

Figure 7.29 shows the relative intensity of the returned light as a func-

tion of distance for three typical arrangements: random, hemispheri-

cal, and concentric circle arrays. The intensities increase with distance

and reach a peak at a certain discrete distance. After that, the intensi-

ties fall off very slowly. Most sensors use the high-sensitivity regions

in these curves. Among the three arrangements, the random array has

the highest sensitivity but the narrowest dynamic range. The displace-

ment sensor using the Y-guide probe provides a resolution of 0.1 μm,

Arrangement o Transmitting o Receiving (R)

Random Hemspherical (H) Concentric (C)

Peak values

H

Intensity (arb. unit) Front Slope R Back slope

C

Distance (arb. unit)

FIGURE 7.29 Relative intensity of returned light for three fi ber-optic

arrangements