Page 398 - Sensors and Control Systems in Manufacturing

P. 398

352

Cha p te r

Se v e n

total volume. The principle of operation is quite simple. The light

from the LED is guided by the optical fiber to the sensing element, in

which the end portion of the fiber is mounted in a stainless steel nee-

dle with a 2.8-mm outer diameter. When liquid is in contact with the

end of the fiber, light enters the fluid efficiently and very little light is

returned. However, when a gas bubble is present, a significant frac-

tion of light is reflected back. With this technique, bubbles as small as

50 μm may be detected with an accuracy of better than 5 percent and

a response time of only 10 μs.

Potential applications of this flow sensor for the control of pro-

cesses in manufacturing systems are widespread—for example,

detection of gas plugs in production wells in the oil industry and

detection of fermenters and distillers in the blood-processing and

pharmaceutical industries.

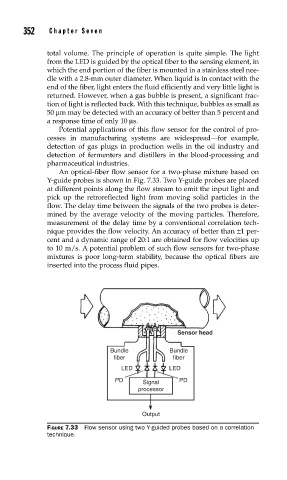

An optical-fiber flow sensor for a two-phase mixture based on

Y-guide probes is shown in Fig. 7.33. Two Y-guide probes are placed

at different points along the flow stream to emit the input light and

pick up the retroreflected light from moving solid particles in the

flow. The delay time between the signals of the two probes is deter-

mined by the average velocity of the moving particles. Therefore,

measurement of the delay time by a conventional correlation tech-

nique provides the flow velocity. An accuracy of better than ±1 per-

cent and a dynamic range of 20:1 are obtained for flow velocities up

to 10 m/s. A potential problem of such flow sensors for two-phase

mixtures is poor long-term stability, because the optical fibers are

inserted into the process fluid pipes.

AB

Sensor head

Bundle Bundle

fiber fiber

LED LED

PD Signal PD

processor

Output

FIGURE 7.33 Flow sensor using two Y-guided probes based on a correlation

technique.