Page 397 - Sensors and Control Systems in Manufacturing

P. 397

Industrial Sensors and Contr ol

Optoelectronic 351

instrument

Optical fiber

connector Optical fiber Sensor

assembly

Microbend Metal

sensor C-ring

Sensor

Bar housing Metal Flowmeter

C-ring body

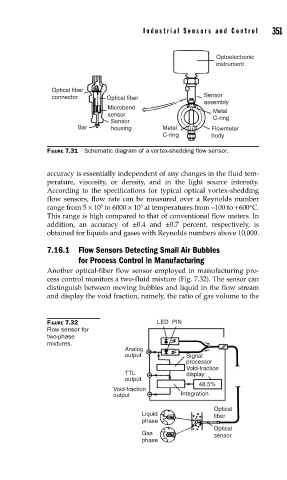

FIGURE 7.31 Schematic diagram of a vortex-shedding fl ow sensor.

accuracy is essentially independent of any changes in the fluid tem-

perature, viscosity, or density, and in the light source intensity.

According to the specifications for typical optical vortex-shedding

flow sensors, flow rate can be measured over a Reynolds number

range from 5 × 10 to 6000 × 10 at temperatures from –100 to +600°C.

3

3

This range is high compared to that of conventional flow meters. In

addition, an accuracy of ±0.4 and ±0.7 percent, respectively, is

obtained for liquids and gases with Reynolds numbers above 10,000.

7.16.1 Flow Sensors Detecting Small Air Bubbles

for Process Control in Manufacturing

Another optical-fiber flow sensor employed in manufacturing pro-

cess control monitors a two-fluid mixture (Fig. 7.32). The sensor can

distinguish between moving bubbles and liquid in the flow stream

and display the void fraction, namely, the ratio of gas volume to the

FIGURE 7.32 LED PIN

Flow sensor for

two-phase

mixtures.

Analog

output Signal

processor

Vold-fraction

TTL display

output

48.5%

Void-fraction

output Integration

Optical

Liquid fiber

phase

Optical

Gas sensor

phase