Page 497 - Sensors and Control Systems in Manufacturing

P. 497

450

Ni ne

Cha p te r

9.5.3 Process Computer

The process computer is constructed from components similar to

those used in a microcomputer system, with the difference that these

components are considerably more powerful because of their pro-

cessing speed and memory capacity. The supporting operating sys-

tems are also more powerful, meaning that many control tasks can be

processed in parallel. For this reason, the process computer is used in

places where it is necessary to solve extensive and complicated auto-

matic control tasks. In such cases, it has the responsibility of control-

ling a complete process (such as a power station), which is made of a

large number of subprocesses. Many smaller control systems, which

operate peripherally, are often subordinated to a process computer. In

such cases, the process computer assumes the role of a coordinating

master computer.

9.6 The NC Controller

Numerical control systems are the most widely used control in

machine tools. A blank or preworked workpiece is machined by NC

machine tools in accordance with specifications given in a technical

drawing and other processing data. Two-, three-, or multiple-axis

machines may be used, depending on the shape of the workpiece and

the processing technology. A two-axis machine tool might be an NC

lathe, for example. A milling machine is an example of a three-axis

machine tool.

In NC machines, sensors and actuators are connected to the pro-

cessor by the manufacturer. The operator or programmer needs to

know the operational principle and the interplay between the con-

troller and machine.

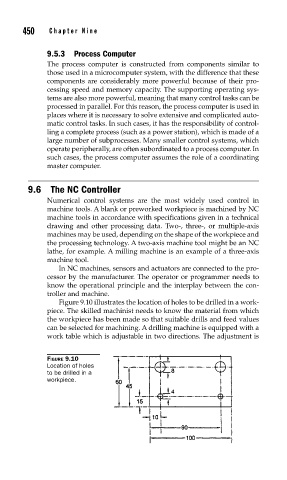

Figure 9.10 illustrates the location of holes to be drilled in a work-

piece. The skilled machinist needs to know the material from which

the workpiece has been made so that suitable drills and feed values

can be selected for machining. A drilling machine is equipped with a

work table which is adjustable in two directions. The adjustment is

FIGURE 9.10

Location of holes

to be drilled in a

workpiece.