Page 500 - Sensors and Control Systems in Manufacturing

P. 500

Communications

In the example just described, the machining of the workpiece 453

takes place only at four different points; only one machining position

is approached. No rule exists as to which path should be taken to

reach this position. Thus, no changes have been made at the work-

piece when the drilling operation occurs, and the table is moved by a

zigzag course to the position for the second drilling operation. This is

referred to as a point-to-point control.

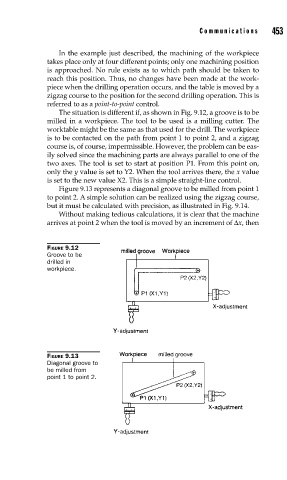

The situation is different if, as shown in Fig. 9.12, a groove is to be

milled in a workpiece. The tool to be used is a milling cutter. The

worktable might be the same as that used for the drill. The workpiece

is to be contacted on the path from point 1 to point 2, and a zigzag

course is, of course, impermissible. However, the problem can be eas-

ily solved since the machining parts are always parallel to one of the

two axes. The tool is set to start at position P1. From this point on,

only the y value is set to Y2. When the tool arrives there, the x value

is set to the new value X2. This is a simple straight-line control.

Figure 9.13 represents a diagonal groove to be milled from point 1

to point 2. A simple solution can be realized using the zigzag course,

but it must be calculated with precision, as illustrated in Fig. 9.14.

Without making tedious calculations, it is clear that the machine

arrives at point 2 when the tool is moved by an increment of Δx, then

FIGURE 9.12

Groove to be

drilled in

workpiece.

FIGURE 9.13

Diagonal groove to

be milled from

point 1 to point 2.