Page 159 - Shale Shakers Drilling Fluid Systems

P. 159

142 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

down. This controls the liquid level in the removal Sequential Treatment

section and still permits most of the fluid in the

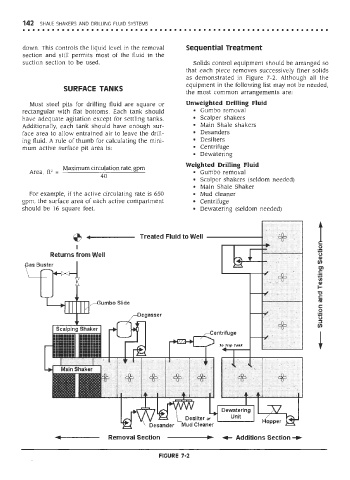

suction section to be used. Solids control equipment should be arranged so

that each piece removes successively finer solids

as demonstrated in Figure 7-2. Although all the

equipment in the following list may not be needed,

SURFACE TANKS

the most common arrangements are:

Most steel pits for drilling fluid are square or Unweighted Drilling Fluid

rectangular with flat bottoms. Each tank should • Gumbo removal

have adequate agitation except for settling tanks. • Scalper shakers

Additionally, each tank should have enough sur- • Main Shale shakers

face area to allow entrained air to leave the drill- • Desanders

ing fluid. A rule of thumb for calculating the mini- • Desilters

mum active surface pit area is: • Centrifuge

• Dewatering

Weighted Drilling Fluid

Maximum circulation rate, gpm

2

Area, ft = • Gumbo removal

40

• Scalper shakers (seldom needed)

• Main Shale Shaker

For example, if the active circulating rate is 650 • Mud cleaner

gpm, the surface area of each active compartment • Centrifuge

should be 16 square feet. • Dewatering (seldom needed)

FIGURE 7-2