Page 170 - Shigley's Mechanical Engineering Design

P. 170

bud29281_ch03_071-146.qxd 11/25/09 4:55PM Page 145 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Load and Stress Analysis 145

3–128 Repeat Prob. 3–126 with a bend radius of in.

1

4

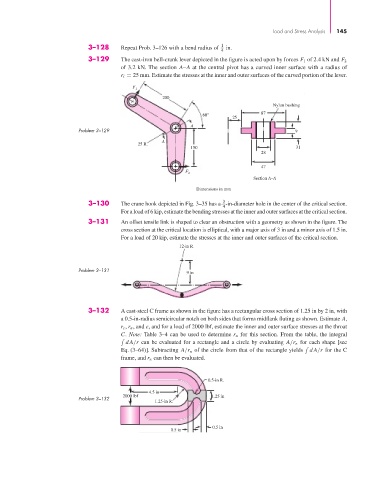

3–129 The cast-iron bell-crank lever depicted in the figure is acted upon by forces F 1 of 2.4 kN and F 2

of 3.2 kN. The section A–A at the central pivot has a curved inner surface with a radius of

r i = 25 mm. Estimate the stresses at the inner and outer surfaces of the curved portion of the lever.

F

1

200

Nylon bushing

60° 87

25

A

Problem 3–129 9

A

25 R.

150 31

28

47

F 2

Section A–A

Dimensions in mm

3

3–130 The crane hook depicted in Fig. 3–35 has a -in-diameter hole in the center of the critical section.

4

For a load of 6 kip, estimate the bending stresses at the inner and outer surfaces at the critical section.

3–131 An offset tensile link is shaped to clear an obstruction with a geometry as shown in the figure. The

cross section at the critical location is elliptical, with a major axis of 3 in and a minor axis of 1.5 in.

For a load of 20 kip, estimate the stresses at the inner and outer surfaces of the critical section.

12-in R.

Problem 3–131 9 in

3–132 A cast-steel C frame as shown in the figure has a rectangular cross section of 1.25 in by 2 in, with

a 0.5-in-radius semicircular notch on both sides that forms midflank fluting as shown. Estimate A,

r c , r n , and e, and for a load of 2000 lbf, estimate the inner and outer surface stresses at the throat

C. Note: Table 3–4 can be used to determine r n for this section. From the table, the integral

dA/r can be evaluated for a rectangle and a circle by evaluating A/r n for each shape [see

Eq. (3–64)]. Subtracting A/r n of the circle from that of the rectangle yields dA/r for the C

frame, and r n can then be evaluated.

0.5-in R.

4.5 in

2000 lbf 1.25 in

Problem 3–132

1.25-in R.

0.5 in

0.5 in