Page 399 - Shigley's Mechanical Engineering Design

P. 399

bud29281_ch07_358-408.qxd 12/8/09 12:52PM Page 374 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

374 Mechanical Engineering Design

EXAMPLE 7–2

This example problem is part of a larger case study. See Chap. 18 for the full

context.

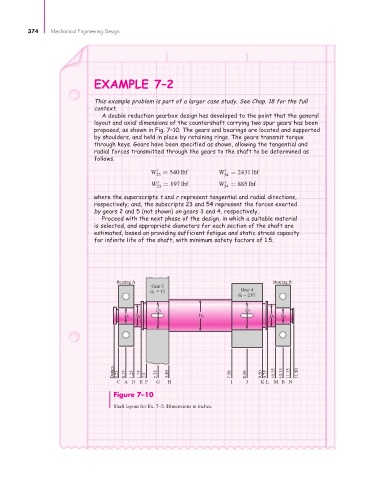

A double reduction gearbox design has developed to the point that the general

layout and axial dimensions of the countershaft carrying two spur gears has been

proposed, as shown in Fig. 7–10. The gears and bearings are located and supported

by shoulders, and held in place by retaining rings. The gears transmit torque

through keys. Gears have been specified as shown, allowing the tangential and

radial forces transmitted through the gears to the shaft to be determined as

follows.

W t = 540 lbf W t = 2431 lbf

23 54

W r = 197 lbf W r = 885 lbf

23 54

where the superscripts t and r represent tangential and radial directions,

respectively; and, the subscripts 23 and 54 represent the forces exerted

by gears 2 and 5 (not shown) on gears 3 and 4, respectively.

Proceed with the next phase of the design, in which a suitable material

is selected, and appropriate diameters for each section of the shaft are

estimated, based on providing sufficient fatigue and static stress capacity

for infinite life of the shaft, with minimum safety factors of 1.5.

Bearing A Bearing B

Gear 3

d 3 12 Gear 4

d 4 2.67

D 3 D 5

D 1 D 2 D 4 D 6 D 7

Datum 0.25 0.75 1.25 1.75 2.0 2.75 3.50 7.50 8.50 9.50 9.75 10.25 10.75 11.25 11.50

CA D E F G H I J K L M B N

Figure 7–10

Shaft layout for Ex. 7–2. Dimensions in inches.