Page 432 - Shigley's Mechanical Engineering Design

P. 432

bud29281_ch07_358-408.qxd 12/8/09 12:52PM Page 407 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Shafts and Shaft Components 407

7–31 For a uniform-diameter shaft, does hollowing the shaft increase or decrease the critical

speed?

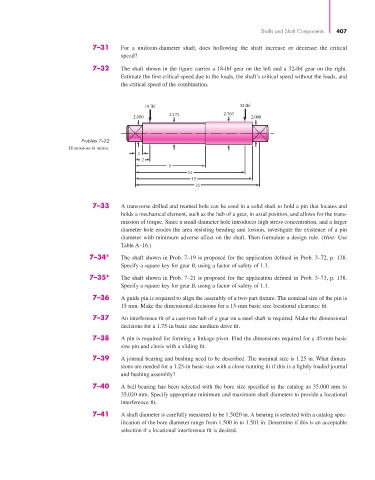

7–32 The shaft shown in the figure carries a 18-lbf gear on the left and a 32-lbf gear on the right.

Estimate the first critical speed due to the loads, the shaft’s critical speed without the loads, and

the critical speed of the combination.

18 lbf 32 lbf

2.472 2.763

2.000 2.000

Problem 7–32

Dimensions in inches.

1

2

9

14

15

16

7–33 A transverse drilled and reamed hole can be used in a solid shaft to hold a pin that locates and

holds a mechanical element, such as the hub of a gear, in axial position, and allows for the trans-

mission of torque. Since a small-diameter hole introduces high stress concentration, and a larger

diameter hole erodes the area resisting bending and torsion, investigate the existence of a pin

diameter with minimum adverse affect on the shaft. Then formulate a design rule. (Hint: Use

Table A–16.)

7–34* The shaft shown in Prob. 7–19 is proposed for the application defined in Prob. 3–72, p. 138.

Specify a square key for gear B, using a factor of safety of 1.1.

7–35* The shaft shown in Prob. 7–21 is proposed for the application defined in Prob. 3–73, p. 138.

Specify a square key for gear B, using a factor of safety of 1.1.

7–36 A guide pin is required to align the assembly of a two-part fixture. The nominal size of the pin is

15 mm. Make the dimensional decisions for a 15-mm basic size locational clearance fit.

7–37 An interference fit of a cast-iron hub of a gear on a steel shaft is required. Make the dimensional

decisions for a 1.75-in basic size medium drive fit.

7–38 A pin is required for forming a linkage pivot. Find the dimensions required for a 45-mm basic

size pin and clevis with a sliding fit.

7–39 A journal bearing and bushing need to be described. The nominal size is 1.25 in. What dimen-

sions are needed for a 1.25-in basic size with a close running fit if this is a lightly loaded journal

and bushing assembly?

7–40 A ball bearing has been selected with the bore size specified in the catalog as 35.000 mm to

35.020 mm. Specify appropriate minimum and maximum shaft diameters to provide a locational

interference fit.

7–41 A shaft diameter is carefully measured to be 1.5020 in. A bearing is selected with a catalog spec-

ification of the bore diameter range from 1.500 in to 1.501 in. Determine if this is an acceptable

selection if a locational interference fit is desired.