Page 497 - Shigley's Mechanical Engineering Design

P. 497

bud29281_ch08_409-474.qxd 12/18/09 2:52 PM Page 472 epg Disk1:Desktop Folder:TEMPWORK:Don't-Delete Jobs:MHDQ196/Budynas:

472 Mechanical Engineering Design

Holes for M12 1.75 bolts

8 mm thick

36 12 kN

Problem 8–76 32

64

Dimensions in millimeters.

36

200

Column

3

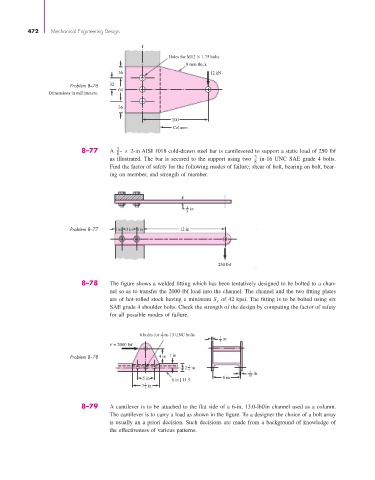

8–77 A - × 2-in AISI 1018 cold-drawn steel bar is cantilevered to support a static load of 250 lbf

8

as illustrated. The bar is secured to the support using two 3 in-16 UNC SAE grade 4 bolts.

8

Find the factor of safety for the following modes of failure: shear of bolt, bearing on bolt, bear-

ing on member, and strength of member.

3 in

8

Problem 8–77 1 in 3 in 1 in 12 in

250 lbf

8–78 The figure shows a welded fitting which has been tentatively designed to be bolted to a chan-

nel so as to transfer the 2000-lbf load into the channel. The channel and the two fitting plates

are of hot-rolled stock having a minimum S y of 42 kpsi. The fitting is to be bolted using six

SAE grade 4 shoulder bolts. Check the strength of the design by computing the factor of safety

for all possible modes of failure.

1

6 holes for in-13 UNC bolts

2 1 in

4

F = 2000 lbf

Problem 8–78 4 in 1 in

2 1 in

4

3 in

5 in 8 in 16

8 in [ 11.5

1

7in

2

8–79 A cantilever is to be attached to the flat side of a 6-in, 13.0-lbf/in channel used as a column.

The cantilever is to carry a load as shown in the figure. To a designer the choice of a bolt array

is usually an a priori decision. Such decisions are made from a background of knowledge of

the effectiveness of various patterns.