Page 501 - Shigley's Mechanical Engineering Design

P. 501

bud29281_ch09_475-516.qxd 12/16/2009 7:12 pm Page 476 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

476 Mechanical Engineering Design

Form can more readily pursue function with the help of joining processes such as weld-

ing, brazing, soldering, cementing, and gluing—processes that are used extensively in

manufacturing today. Whenever parts have to be assembled or fabricated, there is usu-

ally good cause for considering one of these processes in preliminary design work.

Particularly when sections to be joined are thin, one of these methods may lead to sig-

nificant savings. The elimination of individual fasteners, with their holes and assembly

costs, is an important factor. Also, some of the methods allow rapid machine assembly,

furthering their attractiveness.

Riveted permanent joints were common as the means of fastening rolled steel

shapes to one another to form a permanent joint. The childhood fascination of seeing a

cherry-red hot rivet thrown with tongs across a building skeleton to be unerringly

caught by a person with a conical bucket, to be hammered pneumatically into its final

shape, is all but gone. Two developments relegated riveting to lesser prominence.

The first was the development of high-strength steel bolts whose preload could be

controlled. The second was the improvement of welding, competing both in cost and in

latitude of possible form.

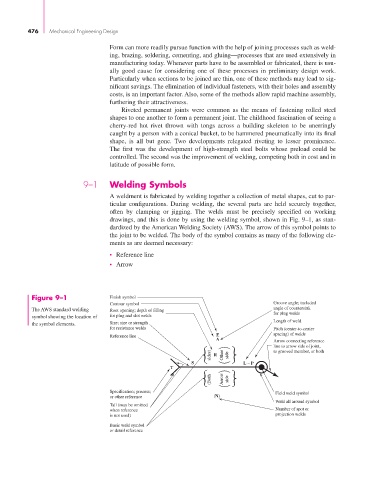

9–1 Welding Symbols

A weldment is fabricated by welding together a collection of metal shapes, cut to par-

ticular configurations. During welding, the several parts are held securely together,

often by clamping or jigging. The welds must be precisely specified on working

drawings, and this is done by using the welding symbol, shown in Fig. 9–1, as stan-

dardized by the American Welding Society (AWS). The arrow of this symbol points to

the joint to be welded. The body of the symbol contains as many of the following ele-

ments as are deemed necessary:

• Reference line

• Arrow

Figure 9–1 Finish symbol

Contour symbol Groove angle; included

The AWS standard welding Root opening; depth of filling angle of countersink

for plug welds

symbol showing the location of for plug and slot welds

Length of weld

the symbol elements. Size; size or strength

for resistance welds Pitch (center-to-center

F spacing) of welds

Reference line

A

Arrow connecting reference

line to arrow side of joint,

to grooved member, or both

S R Other side L – P

T (Both sides) Arrow

Specification; process; side Field weld symbol

or other reference (N)

Weld all around symbol

Tail (may be omitted

when reference Number of spot or

is not used) projection welds

Basic weld symbol

or detail reference