Page 503 - Shigley's Mechanical Engineering Design

P. 503

bud29281_ch09_475-516.qxd 12/16/2009 7:12 pm Page 478 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

478 Mechanical Engineering Design

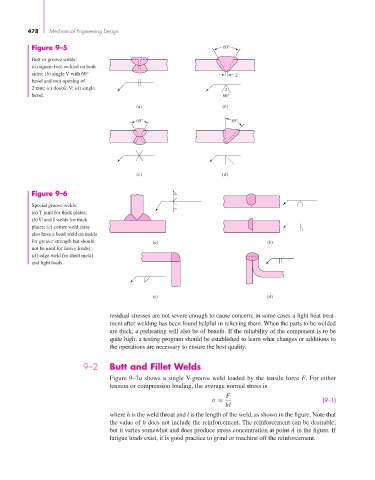

Figure 9–5 60°

Butt or groove welds:

(a) square butt-welded on both

sides; (b) single V with 60° 2

bevel and root opening of

2 mm; (c) double V; (d) single 2

bevel. 60°

(a) (b)

60° 45°

(c) (d)

Figure 9–6

Special groove welds:

(a) T joint for thick plates;

(b) U and J welds for thick

plates; (c) corner weld (may

also have a bead weld on inside

for greater strength but should (a) (b)

not be used for heavy loads);

(d) edge weld for sheet metal

and light loads.

(c) (d)

residual stresses are not severe enough to cause concern; in some cases a light heat treat-

ment after welding has been found helpful in relieving them. When the parts to be welded

are thick, a preheating will also be of benefit. If the reliability of the component is to be

quite high, a testing program should be established to learn what changes or additions to

the operations are necessary to ensure the best quality.

9–2 Butt and Fillet Welds

Figure 9–7a shows a single V-groove weld loaded by the tensile force F. For either

tension or compression loading, the average normal stress is

F

σ = (9–1)

hl

where h is the weld throat and l is the length of the weld, as shown in the figure. Note that

the value of h does not include the reinforcement. The reinforcement can be desirable,

but it varies somewhat and does produce stress concentration at point A in the figure. If

fatigue loads exist, it is good practice to grind or machine off the reinforcement.