Page 502 - Shigley's Mechanical Engineering Design

P. 502

bud29281_ch09_475-516.qxd 12/16/2009 7:12 pm Page 477 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Welding, Bonding, and the Design of Permanent Joints 477

• Basic weld symbols as in Fig. 9–2

• Dimensions and other data

• Supplementary symbols

• Finish symbols

• Tail

• Specification or process

The arrow side of a joint is the line, side, area, or near member to which the arrow

points. The side opposite the arrow side is the other side.

Figures 9–3 to 9–6 illustrate the types of welds used most frequently by designers.

For general machine elements most welds are fillet welds, though butt welds are used a

great deal in designing pressure vessels. Of course, the parts to be joined must be

arranged so that there is sufficient clearance for the welding operation. If unusual joints

are required because of insufficient clearance or because of the section shape, the

design may be a poor one and the designer should begin again and endeavor to synthe-

size another solution.

Since heat is used in the welding operation, there are metallurgical changes in the

parent metal in the vicinity of the weld. Also, residual stresses may be introduced because

of clamping or holding or, sometimes, because of the order of welding. Usually these

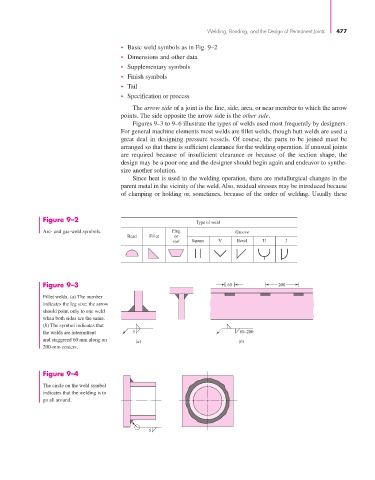

Figure 9–2

Type of weld

Arc- and gas-weld symbols. Plug Groove

Bead Fillet or

slot Square V Bevel U J

Figure 9–3 60 200

Fillet welds. (a) The number

indicates the leg size; the arrow

should point only to one weld

when both sides are the same.

(b) The symbol indicates that

the welds are intermittent 5 60–200

and staggered 60 mm along on (a) (b)

200-mm centers.

Figure 9–4

The circle on the weld symbol

indicates that the welding is to

go all around.

5