Page 493 - Shigley's Mechanical Engineering Design

P. 493

bud29281_ch08_409-474.qxd 12/16/2009 7:11 pm Page 468 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

468 Mechanical Engineering Design

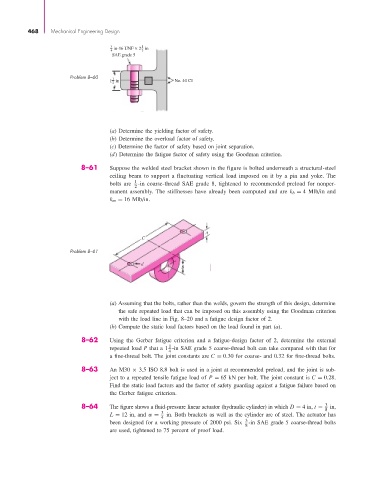

1

3 in-16 UNF × 2in

4 2

SAE grade 5

Problem 8–60 1

1in No. 40 CI

2

(a) Determine the yielding factor of safety.

(b) Determine the overload factor of safety.

(c) Determine the factor of safety based on joint separation.

(d) Determine the fatigue factor of safety using the Goodman criterion.

8–61 Suppose the welded steel bracket shown in the figure is bolted underneath a structural-steel

ceiling beam to support a fluctuating vertical load imposed on it by a pin and yoke. The

1

bolts are -in coarse-thread SAE grade 8, tightened to recommended preload for nonper-

2

manent assembly. The stiffnesses have already been computed and are k b = 4 Mlb/in and

k m = 16 Mlb/in.

A

C

Problem 8–61

d

B

(a) Assuming that the bolts, rather than the welds, govern the strength of this design, determine

the safe repeated load that can be imposed on this assembly using the Goodman criterion

with the load line in Fig. 8–20 and a fatigue design factor of 2.

(b) Compute the static load factors based on the load found in part (a).

8–62 Using the Gerber fatigue criterion and a fatigue-design factor of 2, determine the external

1

repeated load P that a 1 -in SAE grade 5 coarse-thread bolt can take compared with that for

4

a fine-thread bolt. The joint constants are C = 0.30 for coarse- and 0.32 for fine-thread bolts.

8–63 An M30 × 3.5 ISO 8.8 bolt is used in a joint at recommended preload, and the joint is sub-

ject to a repeated tensile fatigue load of P = 65 kN per bolt. The joint constant is C = 0.28.

Find the static load factors and the factor of safety guarding against a fatigue failure based on

the Gerber fatigue criterion.

8–64 The figure shows a fluid-pressure linear actuator (hydraulic cylinder) in which D = 4 in, t = 3 in,

3 8

L = 12 in, and w = 4 in. Both brackets as well as the cylinder are of steel. The actuator has

3

been designed for a working pressure of 2000 psi. Six -in SAE grade 5 coarse-thread bolts

8

are used, tightened to 75 percent of proof load.