Page 277 - Six Sigma Demystified

P. 277

Part 3 s i x s i g m a to o l s 257

licating the experiment, and then implement control mechanisms on the

significant factors as part of the improve stage.

• To model the process for prediction, run a central composite design (de-

scribed in the Glossary and applied as discussed in the “Response Surface

Analysis” topic below). It’s possible the screening design can be extended

with just a few experimental conditions to satisfy this requirement.

• To optimize the process by relocating it to a region of maximum yield,

proceed to response surface analysis (discussed below) or evolutionary

operation techniques (discussed earlier).

Factorial Designs

Minitab

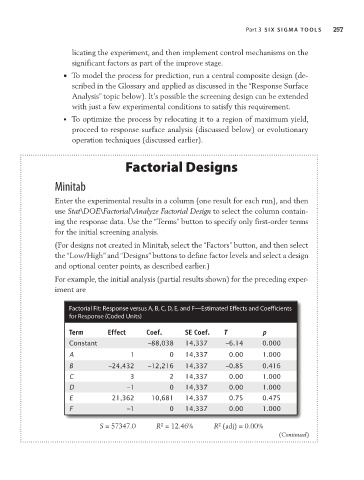

Enter the experimental results in a column (one result for each run), and then

use Stat\DOE\Factorial\Analyze Factorial Design to select the column contain-

ing the response data. Use the “Terms” button to specify only first-order terms

for the initial screening analysis.

(For designs not created in Minitab, select the “Factors” button, and then select

the “Low/High” and “Designs” buttons to define factor levels and select a design

and optional center points, as described earlier.)

For example, the initial analysis (partial results shown) for the preceding exper-

iment are

Factorial Fit: Response versus a, B, C, D, E, and F—Estimated Effects and Coefficients

for Response (Coded units)

Term Effect Coef. SE Coef. T p

Constant –88,038 14,337 –6.14 0.000

A 1 0 14,337 0.00 1.000

B –24,432 –12,216 14,337 –0.85 0.416

C 3 2 14,337 0.00 1.000

D –1 0 14,337 0.00 1.000

E 21,362 10,681 14,337 0.75 0.475

F –1 0 14,337 0.00 1.000

2

S = 57347.0 R = 12.46% R (adj) = 0.00%

2

(Continued)