Page 15 - Six Sigma for electronics design and manufacturing

P. 15

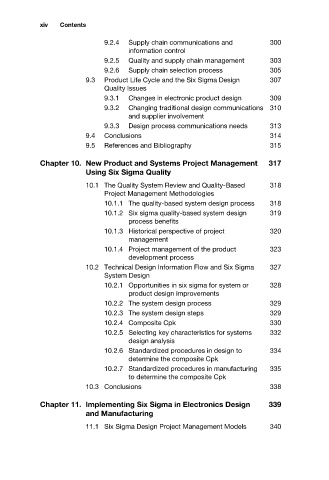

Contents

xiv

9.2.4

information control

303

9.2.5

Quality and supply chain management

305

9.2.6

Supply chain selection process

307

9.3

Product Life Cycle and the Six Sigma Design

Quality Issues

Changes in electronic product design

9.3.1

309

9.3.2

Changing traditional design communications 310

and supplier involvement

Design process communications needs

9.3.3 Supply chain communications and 300

313

9.4 Conclusions 314

9.5 References and Bibliography 315

Chapter 10. New Product and Systems Project Management 317

Using Six Sigma Quality

10.1 The Quality System Review and Quality-Based 318

Project Management Methodologies

10.1.1 The quality-based system design process 318

10.1.2 Six sigma quality-based system design 319

process benefits

10.1.3 Historical perspective of project 320

management

10.1.4 Project management of the product 323

development process

10.2 Technical Design Information Flow and Six Sigma 327

System Design

10.2.1 Opportunities in six sigma for system or 328

product design improvements

10.2.2 The system design process 329

10.2.3 The system design steps 329

10.2.4 Composite Cpk 330

10.2.5 Selecting key characteristics for systems 332

design analysis

10.2.6 Standardized procedures in design to 334

determine the composite Cpk

10.2.7 Standardized procedures in manufacturing 335

to determine the composite Cpk

10.3 Conclusions 338

Chapter 11. Implementing Six Sigma in Electronics Design 339

and Manufacturing

11.1 Six Sigma Design Project Management Models 340