Page 19 - Six Sigma for electronics design and manufacturing

P. 19

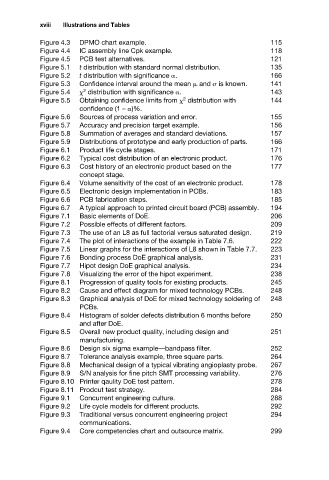

Illustrations and Tables

xviii

Figure 4.3

IC assembly line Cpk example.

118

Figure 4.4

PCB test alternatives.

Figure 4.5

121

Figure 5.1

135

t distribution with standard normal distribution.

166

t distribution with significance .

Figure 5.2

Confidence interval around the mean and is known.

Figure 5.3

141

distribution with significance .

2

143

Figure 5.4

Obtaining confidence limits from distribution with

144

Figure 5.5

confidence (1 – )%.

155

Sources of process variation and error.

Figure 5.6

Accuracy and precision target example.

Figure 5.7 DPMO chart example. 2 115

156

Figure 5.8 Summation of averages and standard deviations. 157

Figure 5.9 Distributions of prototype and early production of parts. 166

Figure 6.1 Product life cycle stages. 171

Figure 6.2 Typical cost distribution of an electronic product. 176

Figure 6.3 Cost history of an electronic product based on the 177

concept stage.

Figure 6.4 Volume sensitivity of the cost of an electronic product. 178

Figure 6.5 Electronic design implementation in PCBs. 183

Figure 6.6 PCB fabrication steps. 185

Figure 6.7 A typical approach to printed circuit board (PCB) assembly. 194

Figure 7.1 Basic elements of DoE. 206

Figure 7.2 Possible effects of different factors. 209

Figure 7.3 The use of an L8 as full factorial versus saturated design. 219

Figure 7.4 The plot of interactions of the example in Table 7.6. 222

Figure 7.5 Linear graphs for the interactions of L8 shown in Table 7.7. 223

Figure 7.6 Bonding process DoE graphical analysis. 231

Figure 7.7 Hipot design DoE graphical analysis. 234

Figure 7.8 Visualizing the error of the hipot experiment. 238

Figure 8.1 Progression of quality tools for existing products. 245

Figure 8.2 Cause and effect diagram for mixed technology PCBs. 248

Figure 8.3 Graphical analysis of DoE for mixed technology soldering of 248

PCBs.

Figure 8.4 Histogram of solder defects distribution 6 months before 250

and after DoE.

Figure 8.5 Overall new product quality, including design and 251

manufacturing.

Figure 8.6 Design six sigma example—bandpass filter. 252

Figure 8.7 Tolerance analysis example, three square parts. 264

Figure 8.8 Mechanical design of a typical vibrating angioplasty probe. 267

Figure 8.9 S/N analysis for fine pitch SMT processing variability. 276

Figure 8.10 Printer qaulity DoE test pattern. 278

Figure 8.11 Prodcut test strategy. 284

Figure 9.1 Concurrent engineering culture. 288

Figure 9.2 Life cycle models for different products. 292

Figure 9.3 Traditional versus concurrent engineering project 294

communications.

Figure 9.4 Core competencies chart and outsource matrix. 299