Page 24 - Six Sigma for electronics design and manufacturing

P. 24

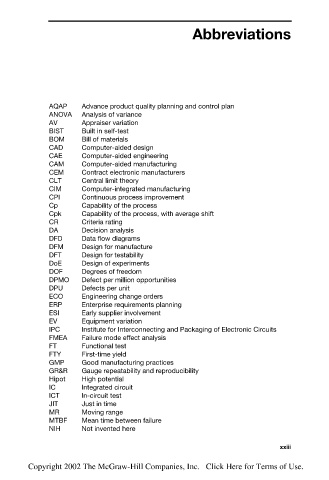

Abbreviations

AQAP

Analysis of variance

ANOVA

Appraiser variation

AV Advance product quality planning and control plan

BIST Built in self-test

BOM Bill of materials

CAD Computer-aided design

CAE Computer-aided engineering

CAM Computer-aided manufacturing

CEM Contract electronic manufacturers

CLT Central limit theory

CIM Computer-integrated manufacturing

CPI Continuous process improvement

Cp Capability of the process

Cpk Capability of the process, with average shift

CR Criteria rating

DA Decision analysis

DFD Data flow diagrams

DFM Design for manufacture

DFT Design for testability

DoE Design of experiments

DOF Degrees of freedom

DPMO Defect per million opportunities

DPU Defects per unit

ECO Engineering change orders

ERP Enterprise requirements planning

ESI Early supplier involvement

EV Equipment variation

IPC Institute for Interconnecting and Packaging of Electronic Circuits

FMEA Failure mode effect analysis

FT Functional test

FTY First-time yield

GMP Good manufacturing practices

GR&R Gauge repeatability and reproducibility

Hipot High potential

IC Integrated circuit

ICT In-circuit test

JIT Just in time

MR Moving range

MTBF Mean time between failure

NIH Not invented here

xxiii

Copyright 2002 The McGraw-Hill Companies, Inc. Click Here for Terms of Use.