Page 177 - Six Sigma for electronics design and manufacturing

P. 177

Six Sigma for Electronics Design and Manufacturing

146

5.2.1 Process capability for large-volume production

The following procedures are recommended when time and resources

are not gating items. It is ideally suited for large-volume manufactur-

ing, where the parts cost is low and the ease of collecting data is high.

These procedures will increase the accuracy of the process capability

and reduce its apparent variation with time.

1. Initial determination of process capability. Historical guidelines

for variable and attribute data are given in Table 5.4. Each sub-

group of data should be taken at a different point in time, prefer-

ably on different days. In this manner, day-to-day variations of the

process could be integrated into the process capability calculations.

There should be no allowance for process average shift in the Cpk

calculations. For low volume applications, the moving range

method should be used because of the low volume required. A dis-

cussion of the moving range method is given in the next section.

2. Regular updates of the process capability. The process capability

should be regularly checked to determine if the process has

changed. If the change is deemed significant using statistical tests,

then a process quality correction project should be initiated to de-

termine the cause of the process deviation. The amount of data re-

quired for checking the process could be less than the original data

needed for initial determination. Determination of can be

achieved either directly from the data or through the R estimator

for variable data. For large-volume production, a sample size of 30

is sufficient to perform this check of process capability for variable

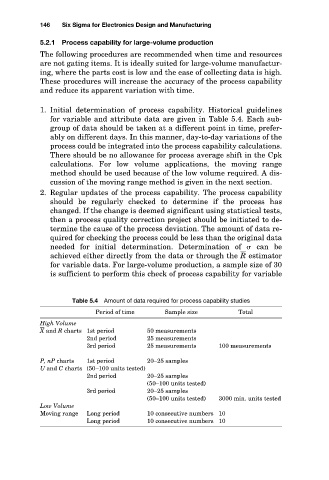

Table 5.4 Amount of data required for process capability studies

Period of time Sample size Total

High Volume

X and R charts 1st period 50 measurements

2nd period 25 measurements

3rd period 25 measurements 100 measurements

P, nP charts 1st period 20–25 samples

U and C charts (50–100 units tested)

2nd period 20–25 samples

(50–100 units tested)

3rd period 20–25 samples

(50–100 units tested) 3000 min. units tested

Low Volume

Moving range Long period 10 consecutive numbers 10

Long period 10 consecutive numbers 10