Page 332 - Solid Waste Analysis and Minimization a Systems Approach

P. 332

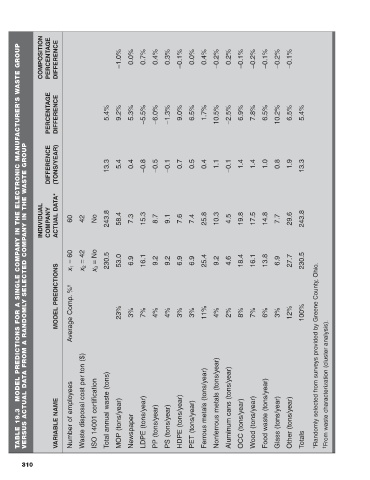

COMPOSITION PERCENTAGE DIFFERENCE −1.0% 0.0% 0.7% 0.4% 0.3% −0.1% 0.0% 0.4% −0.2% 0.2% −0.1% −0.2% −0.1% −0.2% −0.1%

MODEL PREDICTIONS FOR A SINGLE COMPANY IN THE ELECTRONIC MANUFACTURER’S WASTE GROUP

PERCENTAGE DIFFERENCE 5.4% 9.2% 5.3% −5.5% −6.0% −1.3% 9.0% 6.5% 1.7% 10.5% −2.5% 6.9% 7.8% 6.5% 10.2% 6.5% 5.4%

VERSUS ACTUAL DATA FROM A RANDOMLY SELECTED COMPANY IN THE WASTE GROUP

DIFFERENCE (TONS/YEAR) 13.3 5.4 0.4 −0.8 −0.5 −0.1 0.7 0.5 0.4 1.1 −0.1 1.4 1.4 1.0 0.8 1.9 13.3

INDIVIDUAL COMPANY ACTUAL DATA* 60 42 No 243.8 58.4 7.3 15.3 8.7 9.1 7.6 7.4 25.8 10.3 4.5 19.8 17.5 14.8 7.7 29.6 243.8

60 42 No

= x 1 = x 2 = x 3 230.5 53.0 6.9 16.1 9.2 9.2 6.9 6.9 25.4 9.2 4.6 18.4 16.1 13.8 6.9 27.7 230.5

MODEL PREDICTIONS % † Average Comp. 23% 3% 7% 4% 4% 3% 3% 11% 4% 2% 8% 7% 6% 3% 12% 100% *Randomly selected from surveys provided by Greene County, Ohio.

TABLE 19.3 VARIABLE NAME Number of employees Waste disposal cost per ton ($) ISO 14001 certification Total annual waste (tons) MOP (tons/year) Newspaper LDPE (tons/year) PP (tons/year) PS (tons/year) HDPE (tons/year) PET (tons/year) Ferrous metals (tons/year) Nonferrous metals (tons/year) Aluminum cans (tons/year) OCC (tons/year) Wood (tons/year) Food waste (tons/year) Glass (tons/year) Other (tons/year) Totals † From waste characterization (cluster analy

310