Page 39 - Solid Waste Analysis and Minimization a Systems Approach

P. 39

THE SYSTEMS APPROACH FOR WASTE MINIMIZATION 17

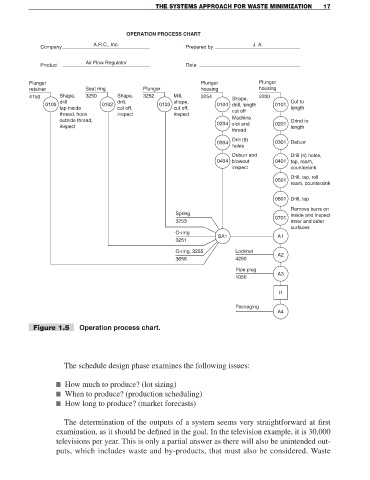

OPERATION PROCESS CHART

A.R.C., Inc. J. A.

Company Prepared by

Air Flow Regulator

Product Date

Plunger Plunger Plunger

retainer Seat ring Plunger housing housing

4150 Shape, 3250 Shape, 3252 Mill, 3254 Shape, 2200

drill drill, shape, Cut to

0105 0102 0103 0104 drill, length 0101

tap inside cut off, cut off, cut off length

thread, hook inspect inspect

outside thread, Machine Grind to

inspect 0204 slot and 0201 length

thread

Drill (8)

0304 0301 Deburr

holes

Deburr and Drill (4) holes,

0404 blowout 0401 tap, ream,

inspect countersink

Drill, tap, roll

0501

ream, countersink

0601 Drill, tap

Remove burrs on

Spring inside and inspect

0701

3253 inner and outer

surfaces

O-ring

SA1 A1

3251

O-ring, 3255 Locknut

A2

3656 4250

Pipe plug

A3

1050

I1

Packaging

A4

Figure 1.5 Operation process chart.

The schedule design phase examines the following issues:

■ How much to produce? (lot sizing)

■ When to produce? (production scheduling)

■ How long to produce? (market forecasts)

The determination of the outputs of a system seems very straightforward at first

examination, as it should be defined in the goal. In the television example, it is 30,000

televisions per year. This is only a partial answer as there will also be unintended out-

puts, which includes waste and by-products, that must also be considered. Waste