Page 202 - Standard Handbook Of Petroleum & Natural Gas Engineering

P. 202

Strength of Materials 187

stress is called the ultimate tensile strength, UTS, of the material. Standard engineering

practice is to define the yield point as 0.2% permanent strain.

When a bar is elongated axially, as in Figure 2-25, it will contract laterally. The

negative ratio of the lateral strain to the axial strain is called Poisson's ratio v. For

isotropic materials, materials that have the same elastic properties in all directions,

Poisson's ratio has a value of about 0.3.

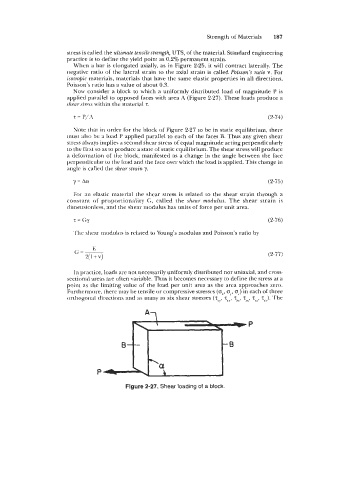

Now consider a block to which a uniformly distributed load of magnitude P is

applied parallel to opposed faces with area A (Figure 2-27). These loads produce a

shear stress within the material T.

T = P/A (2-74)

Note that in order for the block of Figure 2-27 to be in static equilibrium, there

must also be a load P applied parallel to each of the faces B. Thus any given shear

stress always implies a second shear stress of equal magnitude acting perpendicularly

to the first so as to produce a state of static equilibrium. The shear stress will produce

a deformation of the block, manifested as a change in the angle between the face

perpendicular to the load and the face over which the load is applied. This change in

angle is called the shear strain y.

y= Aa (2-75)

For an elastic material the shear stress is related to the shear strain through a

constant of proportionality G, called the shear modulus. The shear strain is

dimensionless, and the shear modulus has units of force per unit area.

T = c;y (2-76)

The shear modulus is related to Young's modulus and Poisson's ratio by

G=- E

2( 1 + v) (2-77)

In practice, loads are not necessarily uniformly distributed nor uniaxial, and cross-

sec~ional areas are often variable. Thus it becomes necessary to define the stress at a

point ab the limiting value of the load per unit area as the area approaches zero.

Furthermore, there may be tensile or compressive stresses (ox, oY, 0,) in each of three

orthogonal directions and as many as six shear stresses (T~", T~~, T~,, T,~, zyL, TJ. The

P

Figure 2-27. Shear loading of a block.