Page 144 - Sustainability in the Process Industry Integration and Optimization

P. 144

Ma s s I n t e g r a t i o n 121

Local treatment unit

Purified water

Freshwater

Purified water Freshwater

Wastewater

Storage n

Operation n Storage ww

Wastewater from continuous operation

Wastewater from central

storage tank for continuous

operation

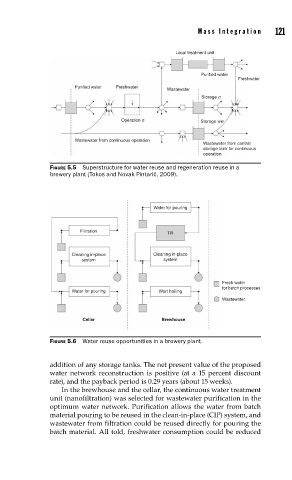

FIGURE 5.5 Superstructure for water reuse and regeneration reuse in a

brewery plant (Tokos and Novak Pintarič, 2009).

Water for pouring

Filtration

TR

Cleaning in-place Cleaning in-place

system system

Fresh water

for batch processes

Water for pouring Wort boiling

Wastewater

Cellar Brewhouse

FIGURE 5.6 Water reuse opportunities in a brewery plant.

addition of any storage tanks. The net present value of the proposed

water network reconstruction is positive (at a 15 percent discount

rate), and the payback period is 0.29 years (about 15 weeks).

In the brewhouse and the cellar, the continuous water treatment

unit (nanofiltration) was selected for wastewater purification in the

optimum water network. Purification allows the water from batch

material pouring to be reused in the clean-in-place (CIP) system, and

wastewater from filtration could be reused directly for pouring the

batch material. All told, freshwater consumption could be reduced