Page 149 - Sustainability in the Process Industry Integration and Optimization

P. 149

126 Cha p te r S i x

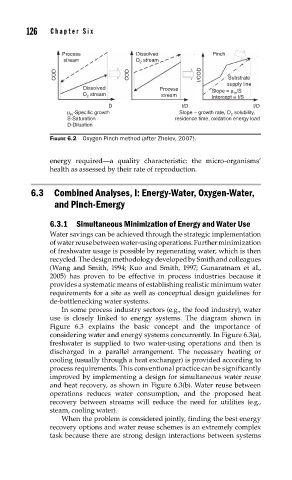

Process Dissolved Pinch

stream O stream

2

COD COD I/COD Substrate

supply line

Dissolved Process

Slope = μ m /S

O stream stream Intercept = I/S

2

D I/D I/D

μ -Specific growth Slope ~ growth rate, O solubility,

m 2

S-Saturation residence time, oxidation energy load

D-Diluation

FIGURE 6.2 Oxygen Pinch method (after Zhelev, 2007).

energy required—a quality characteristic: the micro-organisms’

health as assessed by their rate of reproduction.

6.3 Combined Analyses, I: Energy-Water, Oxygen-Water,

and Pinch-Emergy

6.3.1 Simultaneous Minimization of Energy and Water Use

Water savings can be achieved through the strategic implementation

of water reuse between water-using operations. Further minimization

of freshwater usage is possible by regenerating water, which is then

recycled. The design methodology developed by Smith and colleagues

(Wang and Smith, 1994; Kuo and Smith, 1997; Gunaratnam et al.,

2005) has proven to be effective in process industries because it

provides a systematic means of establishing realistic minimum water

requirements for a site as well as conceptual design guidelines for

de-bottlenecking water systems.

In some process industry sectors (e.g., the food industry), water

use is closely linked to energy systems. The diagram shown in

Figure 6.3 explains the basic concept and the importance of

considering water and energy systems concurrently. In Figure 6.3(a),

freshwater is supplied to two water-using operations and then is

discharged in a parallel arrangement. The necessary heating or

cooling (usually through a heat exchanger) is provided according to

process requirements. This conventional practice can be significantly

improved by implementing a design for simultaneous water reuse

and heat recovery, as shown in Figure 6.3(b). Water reuse between

operations reduces water consumption, and the proposed heat

recovery between streams will reduce the need for utilities (e.g.,

steam, cooling water).

When the problem is considered jointly, finding the best energy

recovery options and water reuse schemes is an extremely complex

task because there are strong design interactions between systems