Page 150 - Sustainability in the Process Industry Integration and Optimization

P. 150

Fu r t h e r A p p l i c a t i o n s o f P r o c e s s I n t e g r a t i o n 127

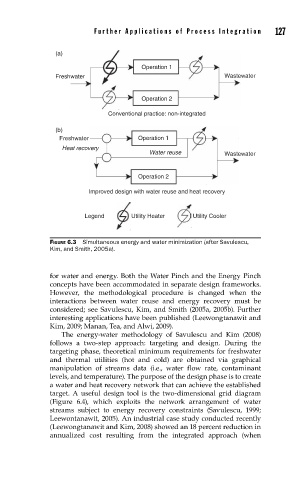

(a)

Operation 1

Freshwater Wastewater

Operation 2

Conventional practice: non-integrated

(b)

Freshwater Operation 1

Heat recovery

Water reuse Wastewater

Operation 2

Improved design with water reuse and heat recovery

Legend Utility Heater Utility Cooler

FIGURE 6.3 Simultaneous energy and water minimization (after Savulescu,

Kim, and Smith, 2005a).

for water and energy. Both the Water Pinch and the Energy Pinch

concepts have been accommodated in separate design frameworks.

However, the methodological procedure is changed when the

interactions between water reuse and energy recovery must be

considered; see Savulescu, Kim, and Smith (2005a, 2005b). Further

interesting applications have been published (Leewongtanawit and

Kim, 2009; Manan, Tea, and Alwi, 2009).

The energy-water methodology of Savulescu and Kim (2008)

follows a two-step approach: targeting and design. During the

targeting phase, theoretical minimum requirements for freshwater

and thermal utilities (hot and cold) are obtained via graphical

manipulation of streams data (i.e., water flow rate, contaminant

levels, and temperature). The purpose of the design phase is to create

a water and heat recovery network that can achieve the established

target. A useful design tool is the two-dimensional grid diagram

(Figure 6.4), which exploits the network arrangement of water

streams subject to energy recovery constraints (Savulescu, 1999;

Leewontanawit, 2005). An industrial case study conducted recently

(Leewongtanawit and Kim, 2008) showed an 18 percent reduction in

annualized cost resulting from the integrated approach (when