Page 166 - Sustainability in the Process Industry Integration and Optimization

P. 166

Fu r t h e r A p p l i c a t i o n s o f P r o c e s s I n t e g r a t i o n 143

CO separation as well as a considerable amount of steam for the

2

stripper.

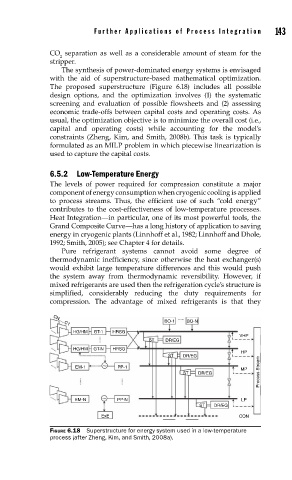

The synthesis of power-dominated energy systems is envisaged

with the aid of superstructure-based mathematical optimization.

The proposed superstructure (Figure 6.18) includes all possible

design options, and the optimization involves (1) the systematic

screening and evaluation of possible flowsheets and (2) assessing

economic trade-offs between capital costs and operating costs. As

usual, the optimization objective is to minimize the overall cost (i.e.,

capital and operating costs) while accounting for the model’s

constraints (Zheng, Kim, and Smith, 2008b). This task is typically

formulated as an MILP problem in which piecewise linearization is

used to capture the capital costs.

6.5.2 Low-Temperature Energy

The levels of power required for compression constitute a major

component of energy consumption when cryogenic cooling is applied

to process streams. Thus, the efficient use of such “cold energy”

contributes to the cost-effectiveness of low-temperature processes.

Heat Integration—in particular, one of its most powerful tools, the

Grand Composite Curve—has a long history of application to saving

energy in cryogenic plants (Linnhoff et al., 1982; Linnhoff and Dhole,

1992; Smith, 2005); see Chapter 4 for details.

Pure refrigerant systems cannot avoid some degree of

thermodynamic inefficiency, since otherwise the heat exchanger(s)

would exhibit large temperature differences and this would push

the system away from thermodynamic reversibility. However, if

mixed refrigerants are used then the refrigeration cycle’s structure is

simplified, considerably reducing the duty requirements for

compression. The advantage of mixed refrigerants is that they

BO-1 BO-N

CN.....C1

HG/HM GT-1 HRSG

VHP

ST DR/EG

HG/HM GT-N HRSG

HP

ST DR/EG

Process Stream

EM-1 PP-1

MP

ST DR/EG

EM-N PP-N LP

ST DR/EG

ExE CON

FIGURE 6.18 Superstructure for energy system used in a low-temperature

process (after Zheng, Kim, and Smith, 2008a).