Page 167 - Sustainability in the Process Industry Integration and Optimization

P. 167

144 Cha p te r S i x

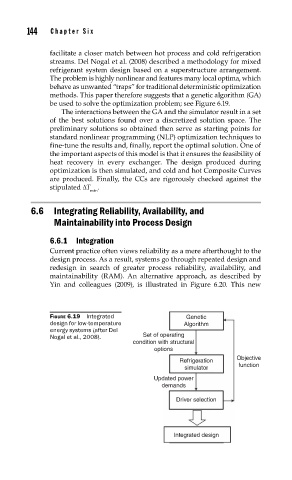

facilitate a closer match between hot process and cold refrigeration

streams. Del Nogal et al. (2008) described a methodology for mixed

refrigerant system design based on a superstructure arrangement.

The problem is highly nonlinear and features many local optima, which

behave as unwanted “traps” for traditional deterministic optimization

methods. This paper therefore suggests that a genetic algorithm (GA)

be used to solve the optimization problem; see Figure 6.19.

The interactions between the GA and the simulator result in a set

of the best solutions found over a discretized solution space. The

preliminary solutions so obtained then serve as starting points for

standard nonlinear programming (NLP) optimization techniques to

fine-tune the results and, finally, report the optimal solution. One of

the important aspects of this model is that it ensures the feasibility of

heat recovery in every exchanger. The design produced during

optimization is then simulated, and cold and hot Composite Curves

are produced. Finally, the CCs are rigorously checked against the

stipulated ΔT .

min

6.6 Integrating Reliability, Availability, and

Maintainability into Process Design

6.6.1 Integration

Current practice often views reliability as a mere afterthought to the

design process. As a result, systems go through repeated design and

redesign in search of greater process reliability, availability, and

maintainability (RAM). An alternative approach, as described by

Yin and colleagues (2009), is illustrated in Figure 6.20. This new

FIGURE 6.19 Integrated Genetic

design for low-temperature Algorithm

energy systems (after Del

Nogal et al., 2008). Set of operating

condition with structural

options

Objective

Refrigeration

simulator function

Updated power

demands

Driver selection

Integrated design