Page 168 - Sustainability in the Process Industry Integration and Optimization

P. 168

Fu r t h e r A p p l i c a t i o n s o f P r o c e s s I n t e g r a t i o n 145

Start

Plan preventive maintenance

interval and tasks to maximize

process availability while

Process meeting risk criteria

Synthesis Stage

Reliability and Risk

Analysis

Is the life cycle cost No

minimized?

Yes

A process with the best life cycle cost

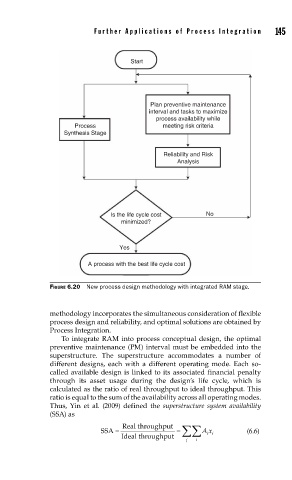

FIGURE 6.20 New process design methodology with integrated RAM stage.

methodology incorporates the simultaneous consideration of flexible

process design and reliability, and optimal solutions are obtained by

Process Integration.

To integrate RAM into process conceptual design, the optimal

preventive maintenance (PM) interval must be embedded into the

superstructure. The superstructure accommodates a number of

different designs, each with a different operating mode. Each so-

called available design is linked to its associated financial penalty

through its asset usage during the design’s life cycle, which is

calculated as the ratio of real throughput to ideal throughput. This

ratio is equal to the sum of the availability across all operating modes.

Thus, Yin et al. (2009) defined the superstructure system availability

(SSA) as

SSA Real throughput ¦¦ Ax (6.6)

ii

Ideal throughput

j i