Page 302 - Sustainability in the Process Industry Integration and Optimization

P. 302

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 279

nd

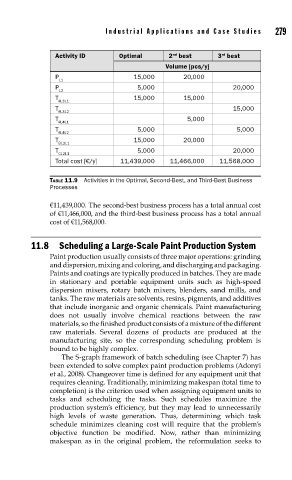

Activity ID Optimal 2 best 3 best

rd

Volume [pcs/y]

P 15,000 20,000

L1

P 5,000 20,000

L2

T 15,000 15,000

AL3L1

T 15,000

AL3L2

T 5,000

AL4L1

T 5,000 5,000

AL4L2

T 15,000 20,000

BL2L1

T 5,000 20,000

CL2L1

Total cost [€/y] 11,439,000 11,466,000 11,568,000

TABLE 11.9 Activities in the Optimal, Second-Best, and Third-Best Business

Processes

€11,439,000. The second-best business process has a total annual cost

of €11,466,000, and the third-best business process has a total annual

cost of €11,568,000.

11.8 Scheduling a Large-Scale Paint Production System

Paint production usually consists of three major operations: grinding

and dispersion, mixing and coloring, and discharging and packaging.

Paints and coatings are typically produced in batches. They are made

in stationary and portable equipment units such as high-speed

dispersion mixers, rotary batch mixers, blenders, sand mills, and

tanks. The raw materials are solvents, resins, pigments, and additives

that include inorganic and organic chemicals. Paint manufacturing

does not usually involve chemical reactions between the raw

materials, so the finished product consists of a mixture of the different

raw materials. Several dozens of products are produced at the

manufacturing site, so the corresponding scheduling problem is

bound to be highly complex.

The S-graph framework of batch scheduling (see Chapter 7) has

been extended to solve complex paint production problems (Adonyi

et al., 2008). Changeover time is defined for any equipment unit that

requires cleaning. Traditionally, minimizing makespan (total time to

completion) is the criterion used when assigning equipment units to

tasks and scheduling the tasks. Such schedules maximize the

production system’s efficiency, but they may lead to unnecessarily

high levels of waste generation. Thus, determining which task

schedule minimizes cleaning cost will require that the problem’s

objective function be modified. Now, rather than minimizing

makespan as in the original problem, the reformulation seeks to