Page 298 - Sustainability in the Process Industry Integration and Optimization

P. 298

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 275

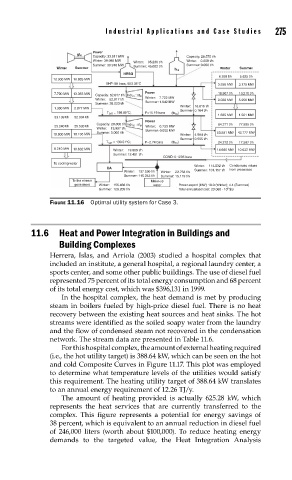

Power

gt 01

Capacity: 33.917 MW Capacity: 28.570 t/h

Winter: 30.085 MW Winter: 0.000 t/h

Winter: 95.230 t/h

Summer: 33.916 MW Summer: 0.000 t/h

Winter Summer Summer: 45.022 t/h Winter Summer

b 02

HRSG

6.289 t/h 5.625 t/h

12.000 MW 16.885 MW

VHP: 90 bara, 503.35°C 3.550 MW 3.175 MW

7.700 MW 13.383 MW Power 18.907 t/h 13.210 t/h

Capacity: 52.017 t/h hdr 01 : st 01

Winter: 52.017 t/h Winter: 7.722 MW 9.038 MW 5.956 MW

Summer: 26.023 t/h Summer: 1.942 MW

Winter: 18.016 t/h

1.300 MW 2.877 MW

Summer: 0.164 t/h

T SAT = 198.89°C; P=15.19 bara (tb 03 )

1.635 MW 1.501 MW

33.139 t/h 52.304 t/h

Power

Capacity: 20.000 t/h hdr 02 : st 01 Winter: 0.733 MW 84.271 t/h 77.935 t/h

25.240 t/h 29.533 t/h

Winter: 13.997 t/h

Summer: 0.000 MW

Summer: 0.000 t/h 50.591 MW 43.777 MW

15.500 MW 18.136 MW Winter: 4.904 t/h

Summer: 0.555 t/h

T SAT = 130.51°C; P=2.74 bara (tb 01 ) 24.272 t/h 17.597 t/h

8.210 MW 10.632 MW 14.660 MW 10.632 MW

Winter: 19.869 t/h

Summer: 12.491 t/h

COND: 0.1235 bara

To cooling water

Winter: 114.832 t/h Condensate return

DA from processes

Winter: 137.590 t/h Winter: 22.758 t/h Summer: 101.157 t/h

Summer: 116.343 t/h Summer: 15.119 t/h

To the stream Make-up

generators Winter: 156.466 t/h water Power export [MW]: 10.0 (Winter); 4.4 (Summer)

Summer: 128.209 t/h Total annualized cost: 23.060 · 10 6 $/y

FIGURE 11.16 Optimal utility system for Case 3.

11.6 Heat and Power Integration in Buildings and

Building Complexes

Herrera, Islas, and Arriola (2003) studied a hospital complex that

included an institute, a general hospital, a regional laundry center, a

sports center, and some other public buildings. The use of diesel fuel

represented 75 percent of its total energy consumption and 68 percent

of its total energy cost, which was $396,131 in 1999.

In the hospital complex, the heat demand is met by producing

steam in boilers fueled by high-price diesel fuel. There is no heat

recovery between the existing heat sources and heat sinks. The hot

streams were identified as the soiled soapy water from the laundry

and the flow of condensed steam not recovered in the condensation

network. The stream data are presented in Table 11.6.

For this hospital complex, the amount of external heating required

(i.e., the hot utility target) is 388.64 kW, which can be seen on the hot

and cold Composite Curves in Figure 11.17. This plot was employed

to determine what temperature levels of the utilities would satisfy

this requirement. The heating utility target of 388.64 kW translates

to an annual energy requirement of 12.26 TJ/y.

The amount of heating provided is actually 625.28 kW, which

represents the heat services that are currently transferred to the

complex. This figure represents a potential for energy savings of

38 percent, which is equivalent to an annual reduction in diesel fuel

of 246,000 liters (worth about $100,000). To reduce heating energy

demands to the targeted value, the Heat Integration Analysis