Page 293 - Sustainability in the Process Industry Integration and Optimization

P. 293

270 C h apter Ele v e n

500

Shifted temperature [°C] 400 Gas turbine exhaust

300

200 Waste

Site steam heat

Driver steam boiler

Gas turbine Boiler Feed Water heating

exhaust

Heat

pump Cooling

water

−10 0 10 20 30 40 50 60

Net heat flow [MW]

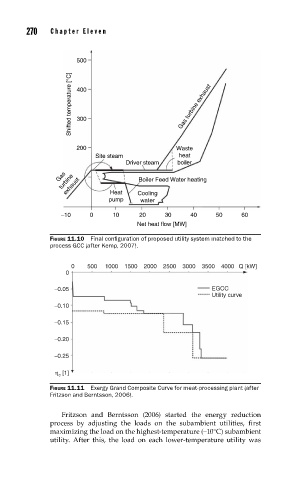

FIGURE 11.10 Final confi guration of proposed utility system matched to the

process GCC (after Kemp, 2007).

0 500 1000 1500 2000 2500 3000 3500 4000 Q [kW]

0

−0.05 EGCC

Utility curve

−0.10

−0.15

−0.20

−0.25

[1]

η c

FIGURE 11.11 Exergy Grand Composite Curve for meat-processing plant (after

Fritzson and Berntsson, 2006).

Fritzson and Berntsson (2006) started the energy reduction

process by adjusting the loads on the subambient utilities, first

maximizing the load on the highest-temperature (−10°C) subambient

utility. After this, the load on each lower-temperature utility was