Page 288 - Sustainability in the Process Industry Integration and Optimization

P. 288

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 265

0.5 t/h 0.5 t/h

Operation 1

8.96 t/h

Loss to Process, 6.265 t/h

Recycle, 23.7 t/h

6.265 t/h 2.45 t/h 2.45 t/h

Operation 2 Operation 3

Loss to Process, 4.8 t/h Recycle, 0.83 t/h

4.8 t/h 0.79 t/h 0.79 t/h

Operation 7 Operation 6

Gain from Process,

0.48 t/h 4.01 t/h

Operation 11

3.53 t/h

Loss to Process,

10.95 t/h

47.56 t/h 31.83 t/h 39.60 t/h 28.60 t/h

Operation 4 Operation 9

Freshwater Gain from Process, Wastewater

169.3 t/h 28.09 t/h 4.38 t/h 175.05 t/h

90.00 t/h 113.72 t/h

Operation 4a

3.39 t/h 3.39 t/h

Operation 5

Net gain from Process,

28.09 t/h

1.00 t/h 8.82 t/h

Operation 2a/8

Loss to Process

8.64 t/h

15.84 t/h 7.20 t/h

Operation 10

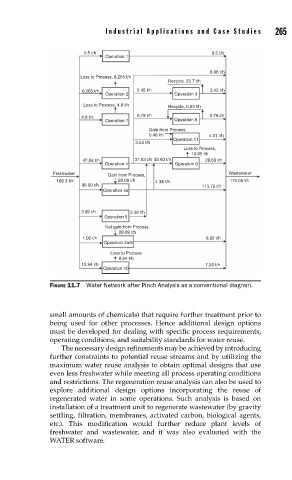

FIGURE 11.7 Water Network after Pinch Analysis as a conventional diagram.

small amounts of chemicals) that require further treatment prior to

being used for other processes. Hence additional design options

must be developed for dealing with specific process requirements,

operating conditions, and suitability standards for water reuse.

The necessary design refinements may be achieved by introducing

further constraints to potential reuse streams and by utilizing the

maximum water reuse analysis to obtain optimal designs that use

even less freshwater while meeting all process operating conditions

and restrictions. The regeneration reuse analysis can also be used to

explore additional design options incorporating the reuse of

regenerated water in some operations. Such analysis is based on

installation of a treatment unit to regenerate wastewater (by gravity

settling, filtration, membranes, activated carbon, biological agents,

etc.). This modification would further reduce plant levels of

freshwater and wastewater, and it was also evaluated with the

WATER software.