Page 284 - Sustainability in the Process Industry Integration and Optimization

P. 284

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 261

28.0° 101.85 kW 65.5° 94.2°

C2 C1 H1

52.1° 507.47 kW

40.0° 111.3°

C3 1 H2

4.54 kW

60.0° 130.2° 186.0°

EC4 2 H3

40.0° 115.3° 197.0°

EC5 3 H4

100.0° 147.3° 296.3°

EC6 4 H5

27.7° 49.4° 89.4° 105.3° 120.0° 137.0° 165.0°

20.0° 310.0°

C1 1 EC5 EC4 EC6 3 2 4 H2

22.3 kW 63.5 kW 116.6 kW 46.6 kW 68.9 kW 92.5 kW 146.6 kW 609.9 kW

(a) Modified HEN Feed 1

28.0° 55.7 kW 54.7° 111.7°

C2 C1 H1

53.2° 436.7 kW

40.0° 111.6°

C3 1 H2

3.79 kW

60.0° 134.5° 186.3°

EC4 2 H3

40.0° 117.0° 196.7°

EC5 3 H4

100.0° 149.8° 294.6°

EC6 4 H5

20.0° 25.8° 49.1° 81.6° 107.0° 124.0° 138.0° 187.0° 310.0°

C1 1 EC5 EC4 EC6 3 2 4 H2

16.7 kW 66.7 kW 93.3 kW 73.2 kW 69.0 kW 64.8 kW 212.7 kW 549.2 kW

(b) Modified HEN Feed 2

28.0° 55.70 kW 48.5° 96.2°

C2 C1 H1

40.0° 39.8° 436.72 kW 111.2°

C3 1 H2

0 kW

60.0° 99.4° 186.0°

EC4 2 H3

40.0° 65.1° 197.1°

EC5 3 H4

100.0° 122.7° 294.8°

EC6 4 H5

20.0° 25.5° 31.9° 45.2° 54.5° 89.4° 112.7° 169.1° 310.0°

C1 1 EC5 EC4 EC6 3 2 4 H2

18.9 kW 22.1 kW 45.1 kW 32.0 kW 116.5 kW 99.1 kW 241.9 kW 608.1 kW

(c) Modified HEN Feed 3

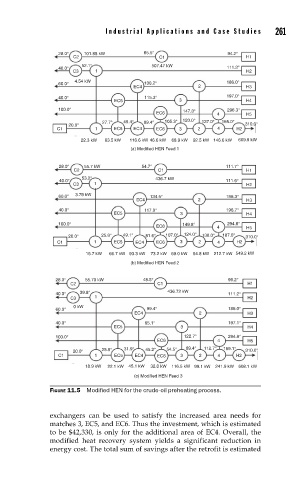

FIGURE 11.5 Modifi ed HEN for the crude-oil preheating process.

exchangers can be used to satisfy the increased area needs for

matches 3, EC5, and EC6. Thus the investment, which is estimated

to be $42,330, is only for the additional area of EC4. Overall, the

modified heat recovery system yields a significant reduction in

energy cost. The total sum of savings after the retrofit is estimated