Page 282 - Sustainability in the Process Industry Integration and Optimization

P. 282

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 259

CP [kW/°C] CP CP

H11 H12

CP = 17.68 28° 65.5° 94.2°

H11 C2 C1 H1

= 17.68 507.5 kW

CP H12 101.9 kW

40.0° 70.0° 111.3°

0.38 C3 1 H2

11.3 kW

60.0° 75.3° 186.0°

1.66 C4 2 H3

25.4 kW

40.0° 129.8° 197.0°

0.84 C5 3 H4

75.8 kW

100.0° 140.3° 296.3°

0.98 C6 4 H5

39.7 kW

CP C11 = 2.92 20.0° 60.0° 65.3° 119.8° 130.3° 158.7° 310.0°

CP = 5.40 C1 H1 1 2 3 4 H2

C12

= 4.23 CP C11 CP CP

CP C13 C1 C1

1 101.7 kW 11.9 kW 2 183.6 kW 56.7 kW 153.5 kW 677.3 kW 3

(a) Initial HEN Feed 1

CP = 9.286 28.0° 54.7° 101.7°

H11 C2 C1

= 2.086 H1

CP H12 55.7 kW 436.7 kW

40.0° 70.0° 111.6°

0.28 C3 1 H2

8.6 kW

60.0° 74.2° 186.3°

1.25 C4 2 H3

17.70 kW

40.0° 122.1° 196.7°

0.87 C5 3 H4

21.4 kW

1.47 100.0° C6 137.3° 4 294.6° H5

54.8 kW

CP = 2.87 20.0° 60.0° 64.2° 112.1° 127.3° 180.5° 310.0°

C11 H1

CP = 4.25 C1 1 2 3 4 H2

C12

CP = 4.49

C13 114.8 kW 11.9 kW 140.4 kW 64.7 kW 231.1 kW 582.8 kW

(b) Initial HEN Feed 2

= 9.85

CP H11 28.0° 48.5° 96.2°

= 2.27 C2 C1

CP H12 46.6 kW 469.9 kW H1

0.27 40.0° C3 70.0° 1 111.2° H2

8.0 kW

1.15 60.0° C4 73.2° 2 186.0° H3

15.1 kW

0.88 40.0° C5 109.4° 3 197.1° H4

61.2 kW

1.41 100.0° C6 127.6° 4 294.8° H5

38.7 kW

= 3.43

CP C11 20.0° 60.0° 63.2° 99.4° 117.6° 172.2° 310.0°

= 4.25

CP C12 C1 H1 1 2 3 4 H2

CP = 4.46

C13 10.9 kW 129.2 kW 77.7 kW 235.1 kW 614.1 kW

137.0 kW

(c) Initial HEN Feed 3

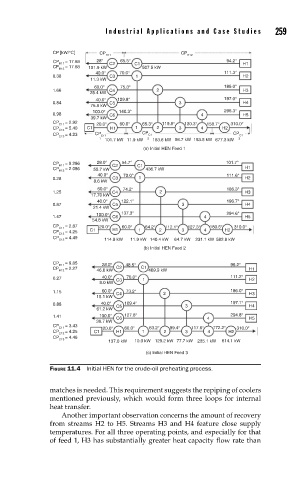

FIGURE 11.4 Initial HEN for the crude-oil preheating process.

matches is needed. This requirement suggests the repiping of coolers

mentioned previously, which would form three loops for internal

heat transfer.

Another important observation concerns the amount of recovery

from streams H2 to H5. Streams H3 and H4 feature close supply

temperatures. For all three operating points, and especially for that

of feed 1, H3 has substantially greater heat capacity flow rate than