Page 278 - Sustainability in the Process Industry Integration and Optimization

P. 278

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 255

4

5

224° 366°

6 H1

60° 150.8° 366°

C 3 H2

238° 760.5 kW 293°

12 H3

52° 123° 293°

C 43 H4

481 kW

38° 54.9° 74° 207.8° 210.5° 238°

C 10 8 7 41 H5

50° 1247 kW 109° 224°

C 2 H6

108° 1235 kW 158°

42 H7

40° 104°

C H8

294.25 kW 83.3°

38° 97.17°

C 12459 kW 40 H9

38° 62.87° 68.11°

C 44 H10

3324 kW

38° 62.05° 63.11°

C C H11

1902 kW

38° 2704 kW 52.5°

C H12

38° 244.5 kW 51.5°

C H13

46° 73.9 kW 96.41°

C H14

53267 kW

38° 46°

C H15

359.6 kW 74.3° 96.3°

38° 48.92° 193°

C C 11 9 H16

563 kW

46° 653.3 kW 53°

C H17

14125 kW

38° 46°

C H18

195.83 kW

38° 46.44°

C H19

856.4 kW

38° 53°

C H20

32.3 kW

60° 67.24°

C H21

7336 kW

38° 60°

C H22

206 kW

38° 102°

C H23

1815.6 kW 88.2° 110° 134.8° 171.7°

60° 385°

C1 40 2 3 4 H 22841 kW

100° 3802 kW 2381 kW 1803 kW 4282.8 kW

C2 5 195°

58.32° 3697.5 kW 192.6°

C3 8

38° 10198.9 kW 55°

C4 10

38° 1413.6 kW 50°

C5 11

8787 kW

184.5° 872.25 kW 193°

C6 12

6

78.56° 95° 41479.7 kW 101.7°

C7 9 7

118.4° 119.3° 13291 kW

118° 4258.8 kW 213.7 kW 124°

C8 43 41 H

48.23° 1151.8 kW 2402.6 kW 49.68°

C9 44

1051.9 kW

51.16° 54.3°

C10 H

101.78° 763.9 kW

95.40° 102°

C11 42 H

5669.4 kW 200 kW

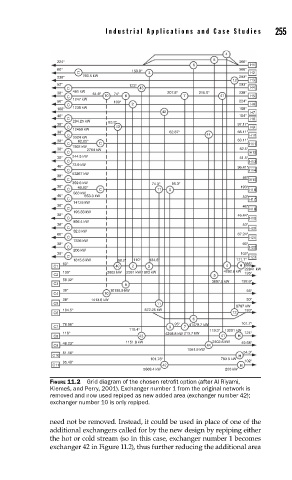

FIGURE 11.2 Grid diagram of the chosen retrofi t option (after Al Riyami,

Klemeš, and Perry, 2001). Exchanger number 1 from the original network is

removed and now used repiped as new added area (exchanger number 42);

exchanger number 10 is only repiped.

need not be removed. Instead, it could be used in place of one of the

additional exchangers called for by the new design by repiping either

the hot or cold stream (so in this case, exchanger number 1 becomes

exchanger 42 in Figure 11.2), thus further reducing the additional area