Page 280 - Sustainability in the Process Industry Integration and Optimization

P. 280

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 257

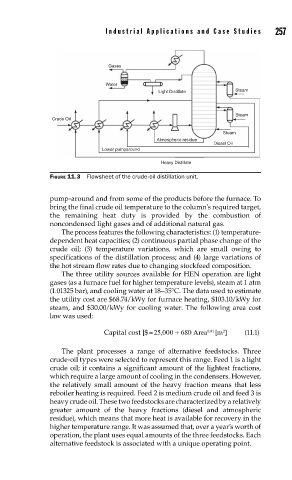

Gases

Water

Light Distillate Steam

Steam

Crude Oil

Steam

Atmospheric residue

Diesel Oil

Lower pumparound

Heavy Distillate

FIGURE 11.3 Flowsheet of the crude-oil distillation unit.

pump-around and from some of the products before the furnace. To

bring the final crude oil temperature to the column’s required target,

the remaining heat duty is provided by the combustion of

noncondensed light gases and of additional natural gas.

The process features the following characteristics: (1) temperature-

dependent heat capacities; (2) continuous partial phase change of the

crude oil; (3) temperature variations, which are small owing to

specifications of the distillation process; and (4) large variations of

the hot stream flow rates due to changing stockfeed composition.

The three utility sources available for HEN operation are light

gases (as a furnace fuel for higher temperature levels), steam at 1 atm

(1.01325 bar), and cooling water at 18–35°C. The data used to estimate

the utility cost are $68.74/kWy for furnace heating, $103.10/kWy for

steam, and $30.00/kWy for cooling water. The following area cost

law was used:

Capital cost [$ = 25,000 + 680 Area 0.81 [m ] (11.1)

2

The plant processes a range of alternative feedstocks. Three

crude-oil types were selected to represent this range. Feed 1 is a light

crude oil; it contains a significant amount of the lightest fractions,

which require a large amount of cooling in the condensers. However,

the relatively small amount of the heavy fraction means that less

reboiler heating is required. Feed 2 is medium crude oil and feed 3 is

heavy crude oil. These two feedstocks are characterized by a relatively

greater amount of the heavy fractions (diesel and atmospheric

residue), which means that more heat is available for recovery in the

higher temperature range. It was assumed that, over a year’s worth of

operation, the plant uses equal amounts of the three feedstocks. Each

alternative feedstock is associated with a unique operating point.