Page 287 - Sustainability in the Process Industry Integration and Optimization

P. 287

264 C h apter Ele v e n

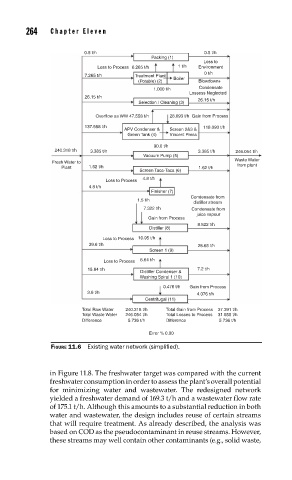

0.5 t/h 0.5 t/h

Packing (1)

Loss to

Loss to Process 6.265 t/h 1 t/h Environment

0 t/h

7.265 t/h Treatment Plant

(Potable) (2) Boiler Blowdown+

1.000 t/h Condensate

Lossess Neglected

26.15 t/h

Selection / Cleaning (3) 26.15 t/h

Overflow as WW 47.558 t/h 28.093 t/h Gain from Process

137.558 t/h 118.093 t/h

APV Condenser & Screen 2&3 &

Green Tank (4) Vincent Press

90.0 t/h

240.318 t/h 3.385 t/h 3.385 t/h 246.054 t/h

Vacuum Pump (5)

Waste Water

Fresh Water to

Plant 1.62 t/h 1.62 t/h from plant

Screen Taca-Taca (6)

Loss to Process 4.8 t/h

4.8 t/h

Finisher (7)

Condensate from

1.5 t/h

distiller stream

7.322 t/h Condensate from

juice vapour

Gain from Process

8.822 t/h

Distiller (8)

Loss to Process 10.95 t/h

39.6 t/h 28.65 t/h

Screen 1 (9)

Loss to Process 8.64 t/h

15.84 t/h 7.2 t/h

Distiller Condenser &

Washing Spiral 1 (10)

0.476 t/h Gain from Process

3.6 t/h 4.076 t/h

Centrifugal (11)

Total Raw Water 240.318 t/h Total Gain from Process 37.391 t/h

Total Waste Water 246.054 t/h Total Losses to Process 31.655 t/h

Difference 5.736 t/h Difference 5.736 t/h

Error % 0.00

FIGURE 11.6 Existing water network (simplifi ed).

in Figure 11.8. The freshwater target was compared with the current

freshwater consumption in order to assess the plant’s overall potential

for minimizing water and wastewater. The redesigned network

yielded a freshwater demand of 169.3 t/h and a wastewater flow rate

of 175.1 t/h. Although this amounts to a substantial reduction in both

water and wastewater, the design includes reuse of certain streams

that will require treatment. As already described, the analysis was

based on COD as the pseudocontaminant in reuse streams. However,

these streams may well contain other contaminants (e.g., solid waste,