Page 294 - Sustainability in the Process Industry Integration and Optimization

P. 294

I n d u s t r i a l A p p l i c a t i o n s a n d Ca s e S t u d i e s 271

maximized. The reduction process began at the highest level (the

highest temperature), since this utility requirement can be satisfied

at a lower cost than refrigeration at lower temperatures. The modified

system was then modeled and simulated in HYSYS, which showed a

5 percent reduction in the shaftwork required.

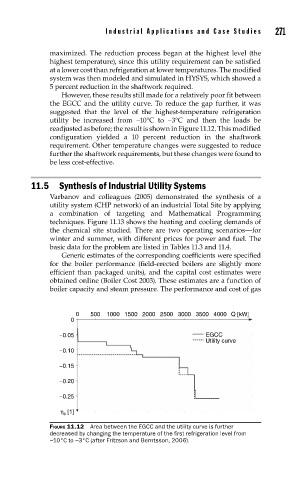

However, these results still made for a relatively poor fit between

the EGCC and the utility curve. To reduce the gap further, it was

suggested that the level of the highest-temperature refrigeration

utility be increased from −10°C to −3°C and then the loads be

readjusted as before; the result is shown in Figure 11.12. This modified

configuration yielded a 10 percent reduction in the shaftwork

requirement. Other temperature changes were suggested to reduce

further the shaftwork requirements, but these changes were found to

be less cost-effective.

11.5 Synthesis of Industrial Utility Systems

Varbanov and colleagues (2005) demonstrated the synthesis of a

utility system (CHP network) of an industrial Total Site by applying

a combination of targeting and Mathematical Programming

techniques. Figure 11.13 shows the heating and cooling demands of

the chemical site studied. There are two operating scenarios—for

winter and summer, with different prices for power and fuel. The

basic data for the problem are listed in Tables 11.3 and 11.4.

Generic estimates of the corresponding coefficients were specified

for the boiler performance (field-erected boilers are slightly more

efficient than packaged units), and the capital cost estimates were

obtained online (Boiler Cost 2003). These estimates are a function of

boiler capacity and steam pressure. The performance and cost of gas

0 500 1000 1500 2000 2500 3000 3500 4000 Q [kW]

0

−0.05 EGCC

Utility curve

−0.10

−0.15

−0.20

−0.25

η [1]

c

FIGURE 11.12 Area between the EGCC and the utility curve is further

decreased by changing the temperature of the fi rst refrigeration level from

−10°C to −3°C (after Fritzson and Berntsson, 2006).