Page 299 - Sustainability in the Process Industry Integration and Optimization

P. 299

276 C h apter Ele v e n

Stream Name T supply T target DH CP

[°C] [°C] [kW] [kW/°C]

1 Hot Soapy water 85 40 23.70 0.53

2 Hot Condensed 80 40 96.32 2.41

steam

3 Cold Laundry 25 55 17.60 0.59

sanitary water

4 Cold Laundry 55 85 77.27 2.58

5 Cold Boiler feed 30 60 7.13 0.24

water

6 Cold Sanitary water 25 60 77.12 2.20

7 Cold Sterilization 30 121 12.50 0.14

8 Cold Swimming pool 25 28 151.67 50.56

water

9 Cold Cooking 30 100 59.63 0.85

10 Cold Heating 18 25 100.82 14.40

11 Cold Bedpan 21 121 4.94 0.05

washers

TABLE 11.6 Process Stream Data of Hospital Complex (Herrera, Islas, and

Arriola, 2003)

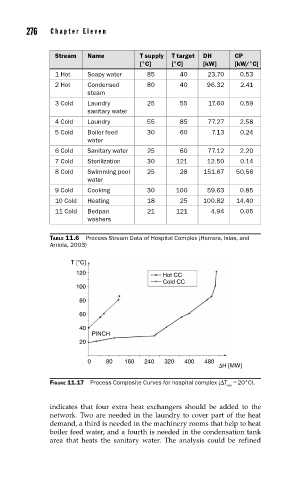

T [°C]

120 Hot CC

Cold CC

100

80

60

40

PINCH

20

0 80 160 240 320 400 480

ΔH [MW]

FIGURE 11.17 Process Composite Curves for hospital complex (∆T = 20°C).

min

indicates that four extra heat exchangers should be added to the

network. Two are needed in the laundry to cover part of the heat

demand, a third is needed in the machinery rooms that help to heat

boiler feed water, and a fourth is needed in the condensation tank

area that heats the sanitary water. The analysis could be refined