Page 351 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 351

324 Ca s e S t u d y 1

Dillon Gym mechanical room. These produce approximately 500 kW while controlling

the steam pressure between the 200-psig high-pressure distribution system and the 15-

psig low-pressure distribution system on campus. This was the first installation where

two Microsteam systems have been operated in parallel.

Central Energy Plant and Systems

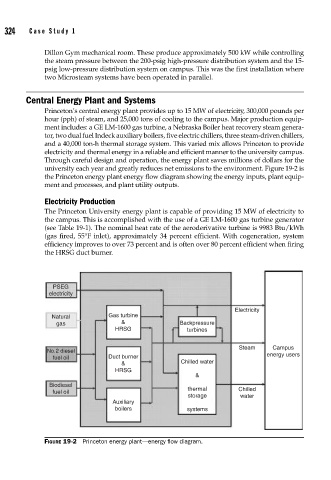

Princeton’s central energy plant provides up to 15 MW of electricity, 300,000 pounds per

hour (pph) of steam, and 25,000 tons of cooling to the campus. Major production equip-

ment includes: a GE LM-1600 gas turbine, a Nebraska Boiler heat recovery steam genera-

tor, two dual fuel Indeck auxiliary boilers, five electric chillers, three steam-driven chillers,

and a 40,000 ton-h thermal storage system. This varied mix allows Princeton to provide

electricity and thermal energy in a reliable and efficient manner to the university campus.

Through careful design and operation, the energy plant saves millions of dollars for the

university each year and greatly reduces net emissions to the environment. Figure 19-2 is

the Princeton energy plant energy flow diagram showing the energy inputs, plant equip-

ment and processes, and plant utility outputs.

Electricity Production

The Princeton University energy plant is capable of providing 15 MW of electricity to

the campus. This is accomplished with the use of a GE LM-1600 gas turbine generator

(see Table 19-1). The nominal heat rate of the aeroderivative turbine is 9983 Btu/kWh

(gas fired, 55°F inlet), approximately 34 percent efficient. With cogeneration, system

efficiency improves to over 73 percent and is often over 80 percent efficient when firing

the HRSG duct burner.

PSEG

electricity

Electricity

Natural Gas turbine

gas & Backpressure

HRSG turbines

Steam Campus

No.2 diesel energy users

fuel oil Duct burner

& Chilled water

HRSG

&

Biodiesel

thermal Chilled

fuel oil

storage water

Auxiliary

boilers systems

FIGURE 19-2 Princeton energy plant—energy fl ow diagram.