Page 385 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 385

358 Ca s e S t u d y 4

Absorber steam input 25,000 lb/h of steam

Absorber output 1,400 tons refrigeration

Absorber efficiency 18 lb of steam/ton-h

Electric chiller efficiency 0.7 kW/ton

TABLE 22-3 Absorption Chiller Performance Data

160,000

140,000

120,000

Steam load (lb/h) 100,000 Campus

80,000

Absorber

60,000

40,000

20,000

0

1-Jan 1-Feb 1-Mar 1-Apr 1-May 1-Jun 1-Jul 1-Aug 1-Sep 1-Oct 1-Nov 1-Dec

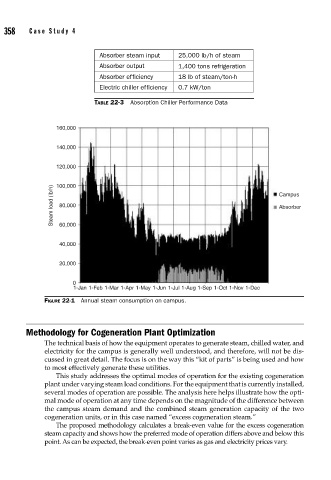

FIGURE 22-1 Annual steam consumption on campus.

Methodology for Cogeneration Plant Optimization

The technical basis of how the equipment operates to generate steam, chilled water, and

electricity for the campus is generally well understood, and therefore, will not be dis-

cussed in great detail. The focus is on the way this “kit of parts” is being used and how

to most effectively generate these utilities.

This study addresses the optimal modes of operation for the existing cogeneration

plant under varying steam load conditions. For the equipment that is currently installed,

several modes of operation are possible. The analysis here helps illustrate how the opti-

mal mode of operation at any time depends on the magnitude of the difference between

the campus steam demand and the combined steam generation capacity of the two

cogeneration units, or in this case named “excess cogeneration steam.”

The proposed methodology calculates a break-even value for the excess cogeneration

steam capacity and shows how the preferred mode of operation differs above and below this

point. As can be expected, the break-even point varies as gas and electricity prices vary.